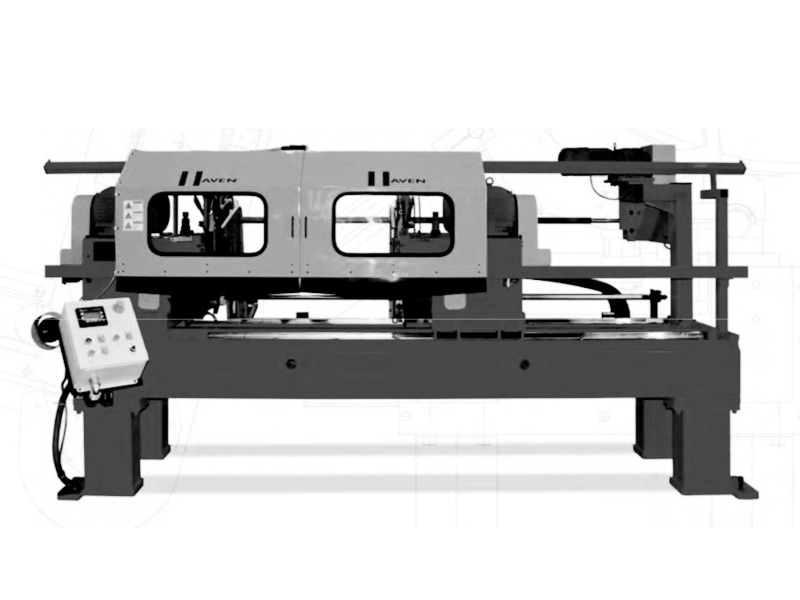

Haven’s pipe end finishing machine, is considered the standard in the pipe end beveling industry. In contrast, our high-speed and economical finishing machines finish both ends of pipes simultaneously. The main advantages of the machine also include hydraulic feed systems, which is fast and precise, as well as quick change of carbide insert knives. What’s more, due to the fact that, one cutting head is stationary, the other, placed opposite it, quickly and accurately adjusts on hardened surfaces, here we have length adjustment, which will certainly be helpful in such a process.

Finishing machines to increase production and quality

The Haven finishing machine is considered the industry standard for beveling pipe ends. Our high-speed and cost-effective finishing machines finish both ends of pipes simultaneously. The same operation cuts both inside and outside diameters and finishes the ends with a smooth surface similar to lathe machining. Fully automated operation combined with carbide knives and hydraulic feeds allow the operator to finish up to 2,500 pipes per hour.

The simplicity of the design and the use of high-quality components ensure low maintenance costs and long machine life. The Haven finishing machine gives your company an edge in today’s pipe manufacturing market.