Customer: Manufacturer of household appliances, an internationally renowned brand, employing more than 20,000 people at various production facilities in Europe, with a turnover of more than 4 billion euros.

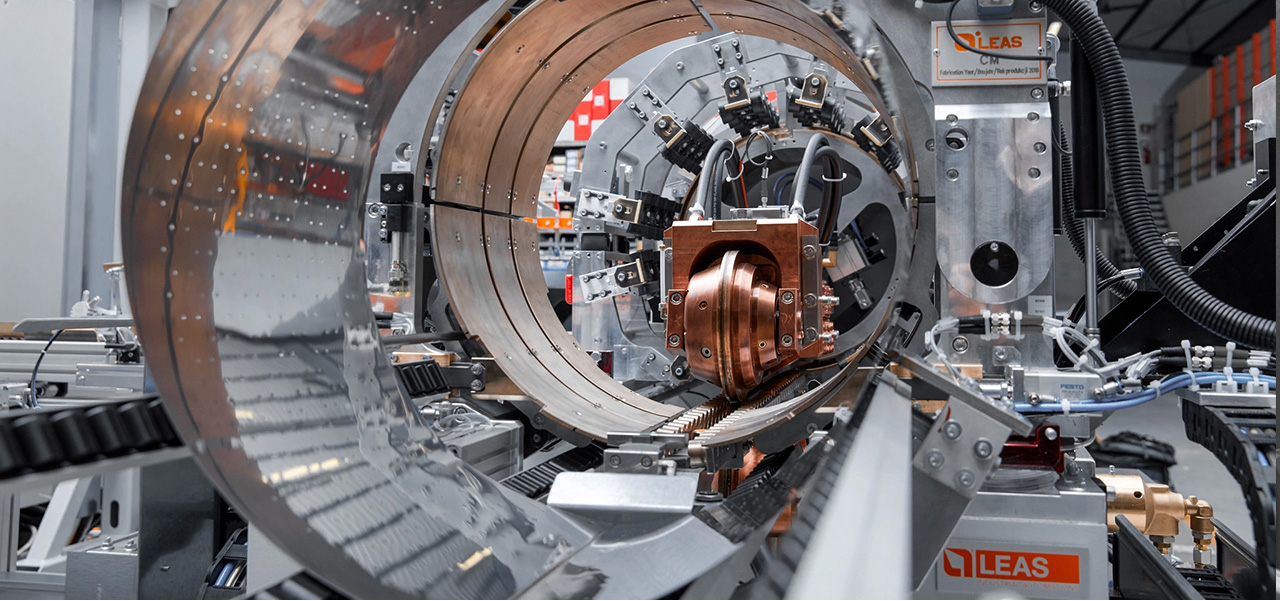

WASHING MACHINE DRUM WELDING SYSTEM

Case study

Domestic appliances

CUSTOMER

A manufacturer of household appliances, an internationally renowned brand, employing more than 20,000 people at various production facilities in Europe, with a turnover of more than 4 billion euros.

BASELINE SITUATION

The customer manufactures washing machines with a work island system, in which the welding process was carried out using welding heads in a mercury bath.

CUSTOMER NEEDS

QUALITY AND PERFORMANCE

Improve the quality and performance standard of a high-end product.

REDUCING EXPOSURE TO RISK

Protecting operators from exposure to risk.

SUSTAINABILITY

A more sustainable welding process.

INTEGRATED INDUSTRY 4.0 SYSTEM

LEAS SOLUTION

By loading this video, you agree to the privacy policy of Youtube.

The system is managed on-site by the operator via an intuitive touch panel and remotely for continuous monitoring and management. It is designed to connect instantly with MES in a 4.0 environment.

Maintenance is no longer a critical issue for the customer, who has eliminated ALL risks to the health of the workforce

QUALITY FIXITY of production has been increased

“In the case of this project, the added value we gave our client was not only the search for the best solution and custom implementation, but also the ability to conceptualize it, starting from the client’s process, with all the associated technical constraints. In any challenge, the probability of success is multiplied if the team collaborates and pursues the goal in a compact manner, and that’s how the LEAS team and the client team worked on this project.”

LEAS project team

WHY LEAS

- SOLUTION

Choosing the ideal technology to use - 100% CUSTOMIZED

Company DNA built on extreme personalization to offer each customer the best solution - COMPREHENSIVE EXPERTISE

From design to commissioning, after-sales service and technology integration - CROSS-INDUSTRY EXPERIENCE

Cross-industry experience in multiple sectors offers innovative solutions compared to industry standards - SUSTAINABILITY

Economic sustainability of investment and total cost of ownership of the plant (Total Cost of Ownership) - ECO-DESIGN

Strict ECO DESIGN policy - CONFIDENCE

Long-term partnership - GOAL ACHIEVEMENT

Achievement of quality and performance targets set by the customer