A new dimension in pipe finishing combined with flexible pipe manufacturing systems.

Pipe end forming

A new dimension in pipe end processing combined with flexible pipe production systems.

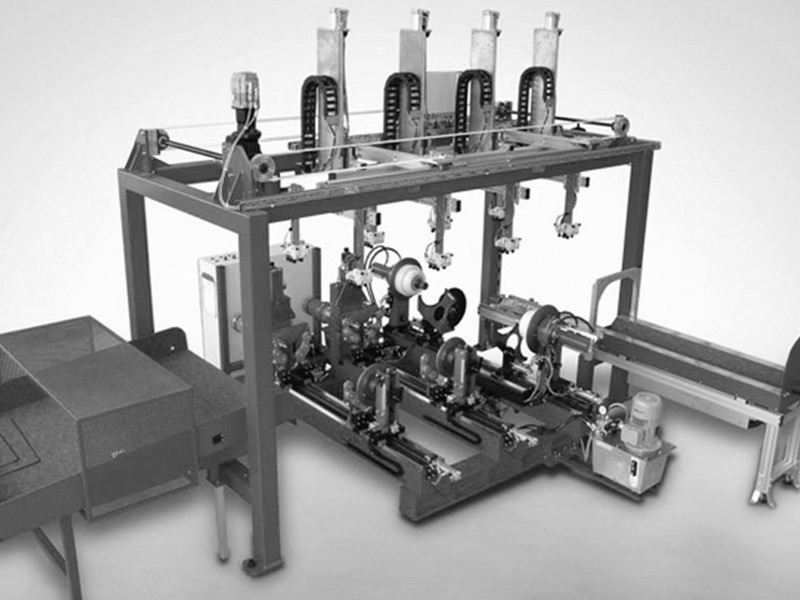

The pipe end processing center can be seamlessly connected to an existing longitudinal welder. A stand-alone version with manual loading and unloading of the pipe is also possible.

The use of a special gantry system for automatic transport of the pipe between stations automatically reduces cycle time and thus increases line efficiency, while improving product quality and all this with minimal space requirements for the entire installation.

The pipe end processing center can be seamlessly connected to an existing longitudinal welder.

A new dimension in pipe end processing combined with flexible pipe production systems.

|

Diameter |

Ø 80 – 400 mm |

|

Pipe length |

250 – 1 250 mm |

|

Material thickness |

0,4 – 1,0 mm |

|

Material |

Steel, stainless steel and galvanized |

|

Cycle time |

Ø 100: 25 sec* Ø 200: 28 sec* Ø 400: 34 sec. |

|

Changeover times |

Ø100 to Ø400: 6 min. Ø80 to Ø100: 12 min. |

*For lengths of less than 500 mm, cycle time is extended to 30s because the expansion units are run one after the other.