The increased strength you’d expect from Haven Manufacturing. Automatic deburring of tubes, bars and profiles.

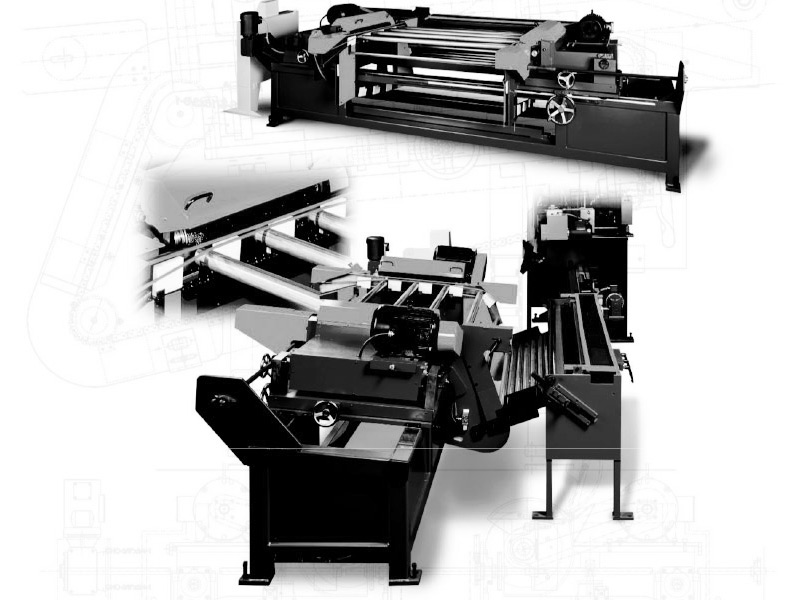

Wire brush deburrers

Operating principle

Cut pipes or rods are automatically transferred between two rotating wire brushes. The length of the workpieces is adjusted by adjusting the position of the moving wire head relative to the wire head, which is stationary. Burrs are removed from both ends simultaneously. As for pipe cross sections, the inner and outer diameters are cleaned at the same time. When brushing squares, rectangles and other shapes, notched guides are used to ensure rotation of the workpiece during brushing.

Brush settings

For best application results, the height of the brushes can be adjusted.