Tailor Laser Welded Blanks (TLWB) are semi-finished products that are joined from steel and aluminum sheets of different thicknesses, alloys, coatings and material properties using laser welding. These semi-finished products are used in the automotive industry to produce BIW parts such as interior doors, floor panels, pillars and rails, etc. using cold and hot stamping processes. TLWB provides customers with;

- Cost reduction by reducing the number of materials, process steps and tools

- Improved crash resistance

- A lightweight solution for BIW

- Increased material utilization

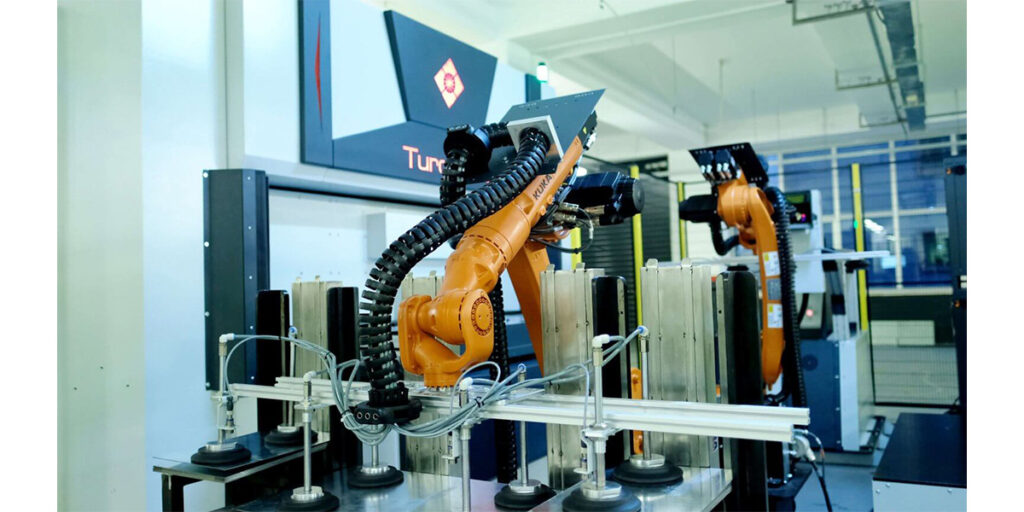

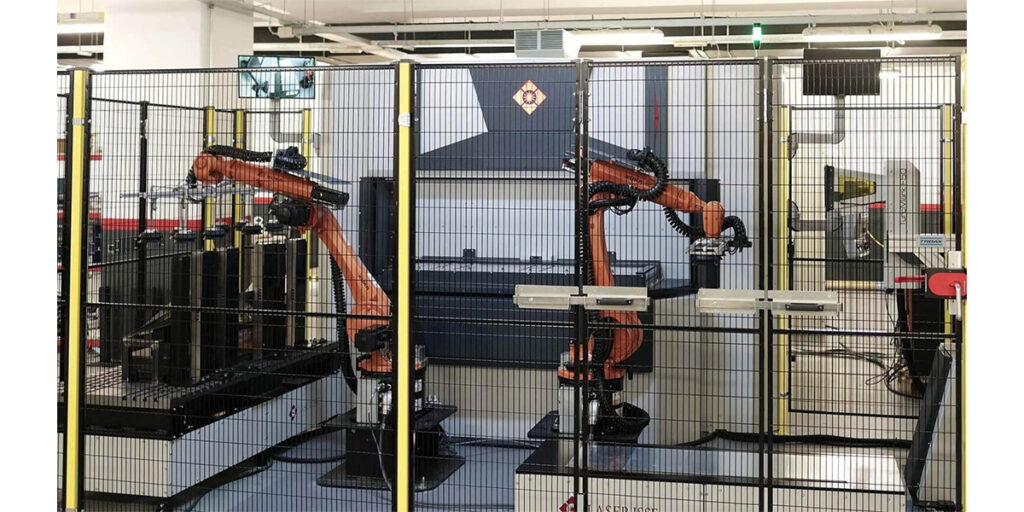

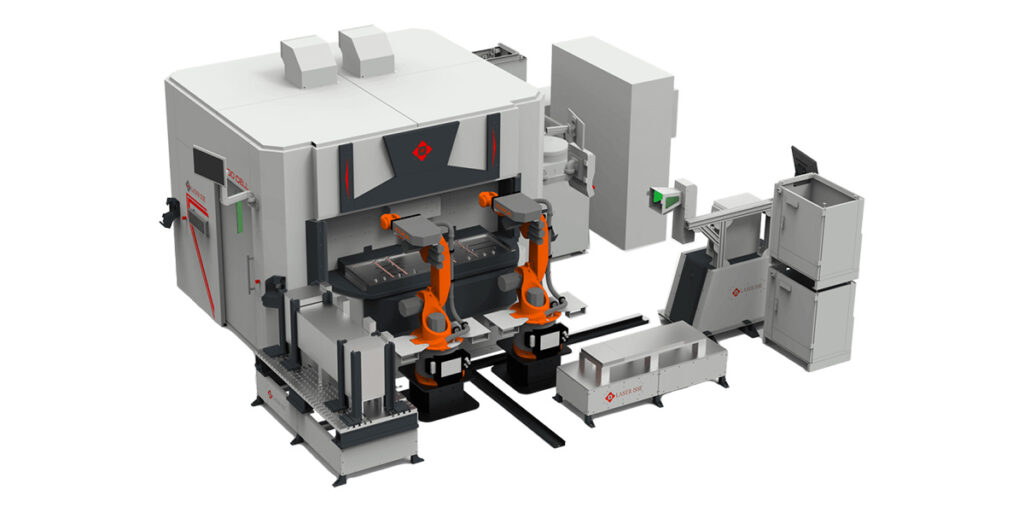

Despite the many benefits, TLWB solutions cannot be widely deployed in BIW at the level they deserve due to limited suppliers and expensive resources. Laser ISSE offers Tier1 suppliers and OEMs the possibility of TLWB availability with a short return on investment through special research and design solutions.

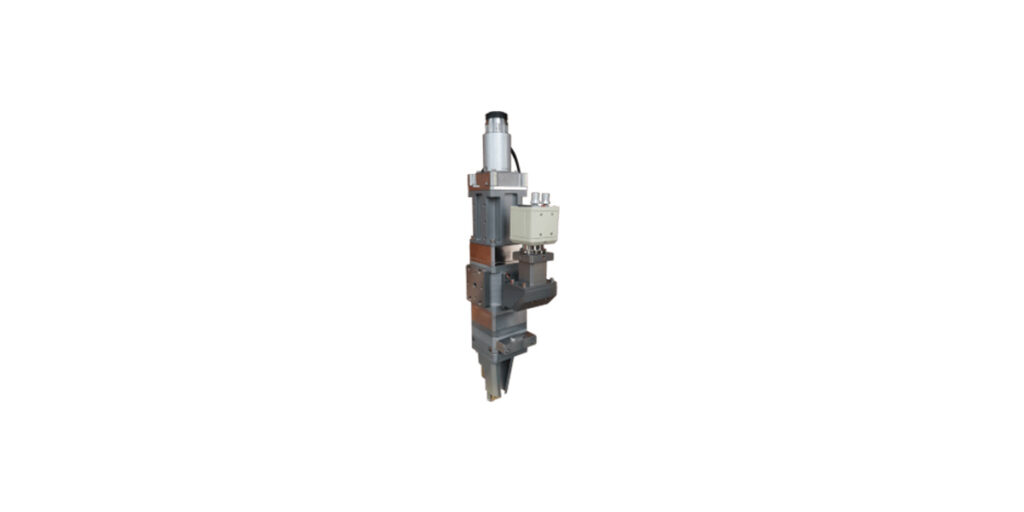

This cutting-edge technology is available, effective and reliable with Laser ISSE’s laser solutions. End users can easily weld different thicknesses and material combinations with Laser ISSE TLWB solutions for both mass production and new part design studies. As the Laser ISSE family, we take care of customers’ requirements and expectations for process stability, productivity, technical capabilities and profitability.