Types of welding

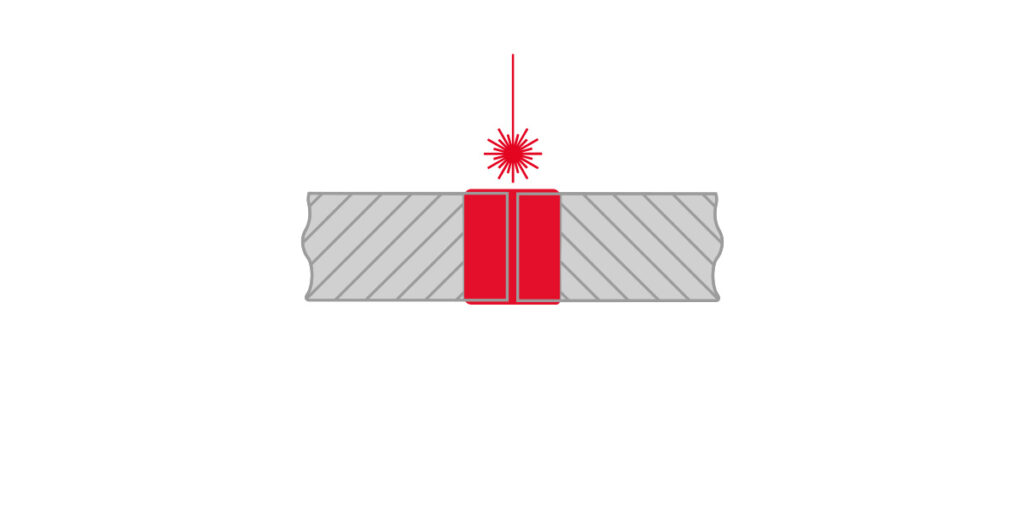

BUTT WELDING

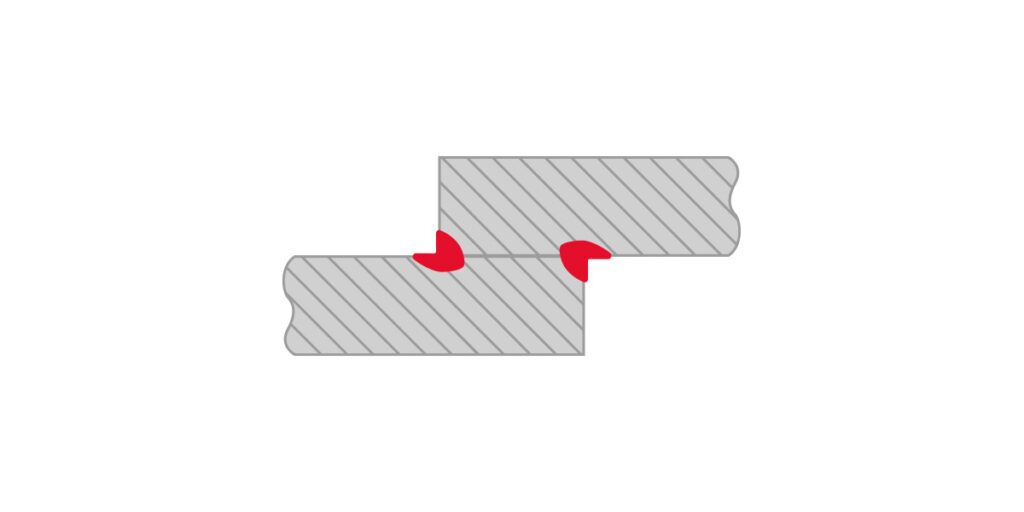

OVERLAP WELDING

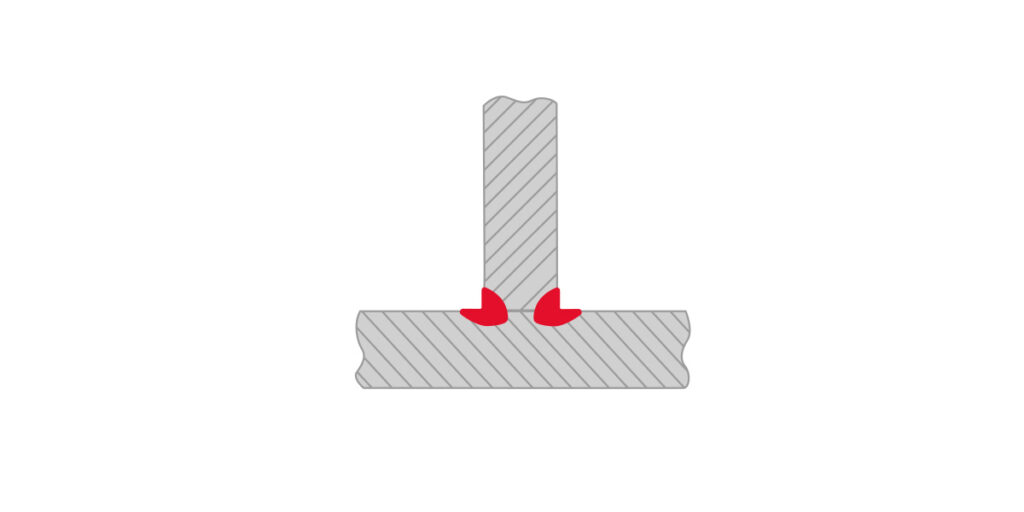

TEE JOINT WELDING

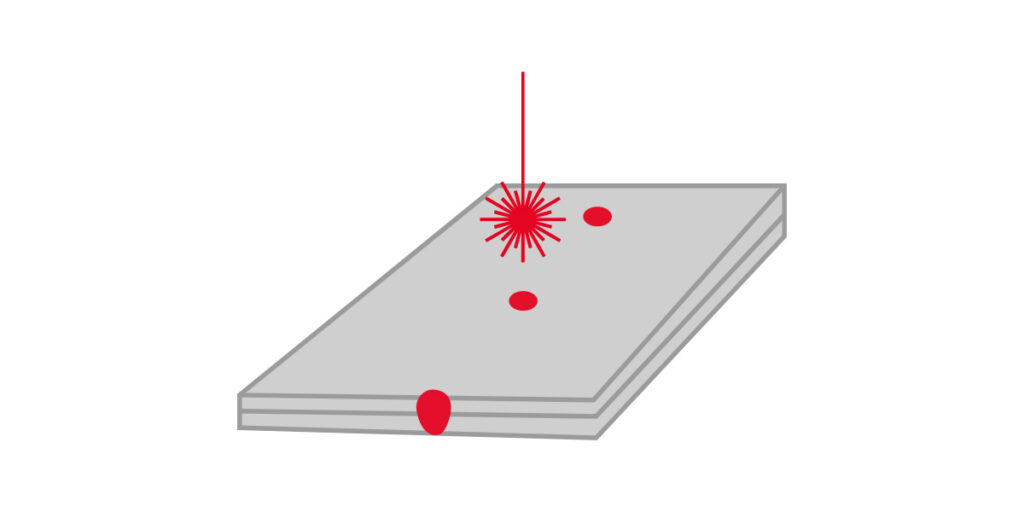

SPOT WELDING

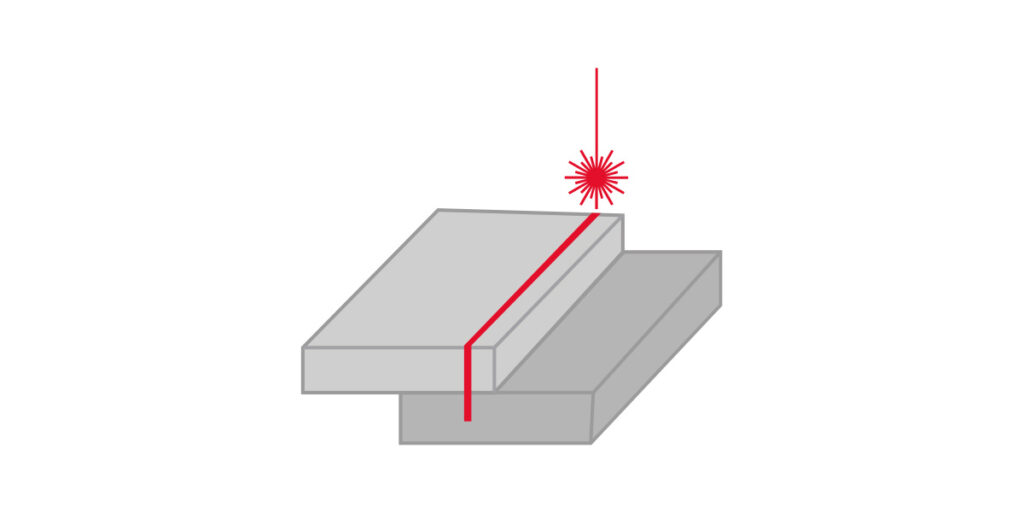

LAP JOINT WELDING

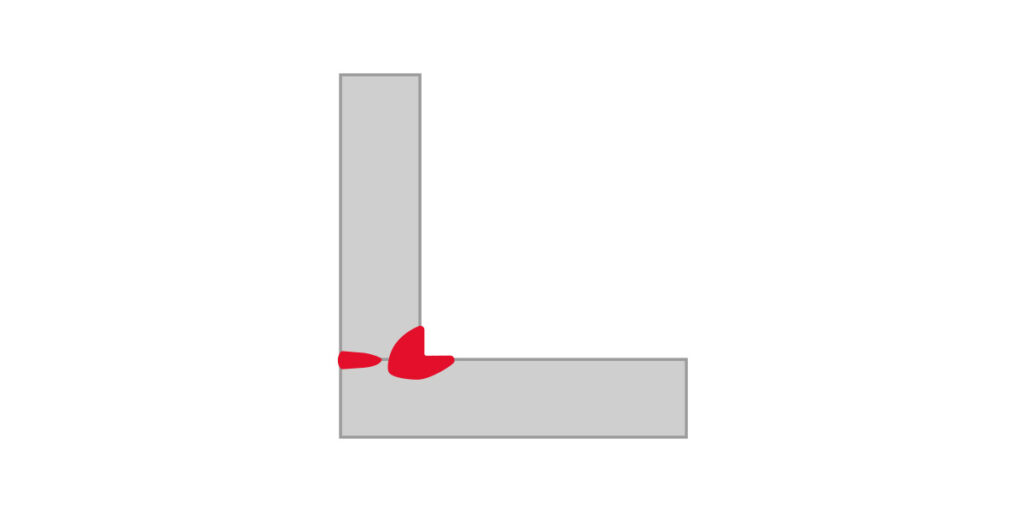

CORNER JOINT WELDING

Types of laser

FIBER LASER

Fiber lasers are effectively used in welding applications thanks to advanced technology

SPI Fiber Lasers has a variMODE, switchable beam delivery function that allows users to customize and optimize beam characteristics (including spot size and beam profile) specific to their needs

Higher power (1 kW – 12 kW) and CW (continuous wave) laser beams reduce process time

DISK LASER

The Trumpf disk laser features a highly stable laser beam quality with a wavelength similar to a fiber laser.

Disk laser technology allows for higher power (2 – 12 kW), with fast and trouble-free application possibilities when processing thick materials and materials with highly reflective surfaces are required.

LASER YAG

The tube-pumped laser welding systems produced by Laser ISSE are effective for spot welding and seam welding due to the high peak powers that can be achieved.

Thanks to its multiple output function, it can be used in many time- or power-division systems. In addition, Nd:YAG lasers can be used with Laserisse handheld devices for handheld use.

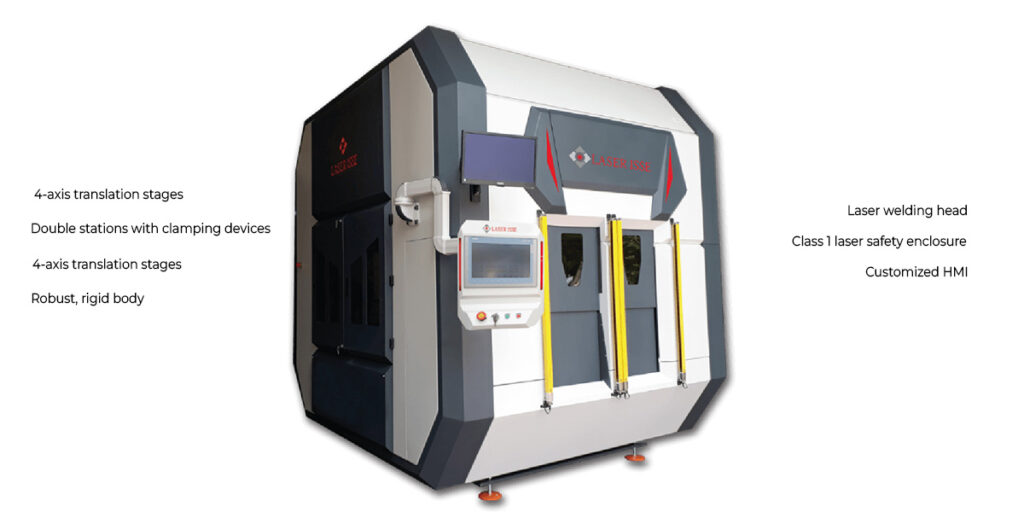

Customized laser welding system