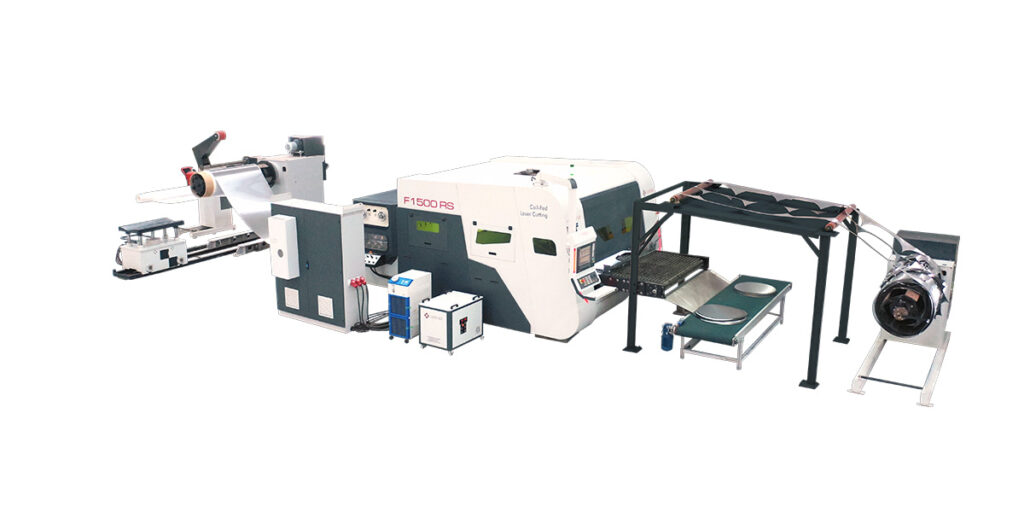

Feeding system for sheet metal coil in laser cutting

Machine used for robotic unloading in laser cuttingęciu laserowym

Gantry crane unloading system used in laser cutting from coil

Bending arm used in laser cutting from coil

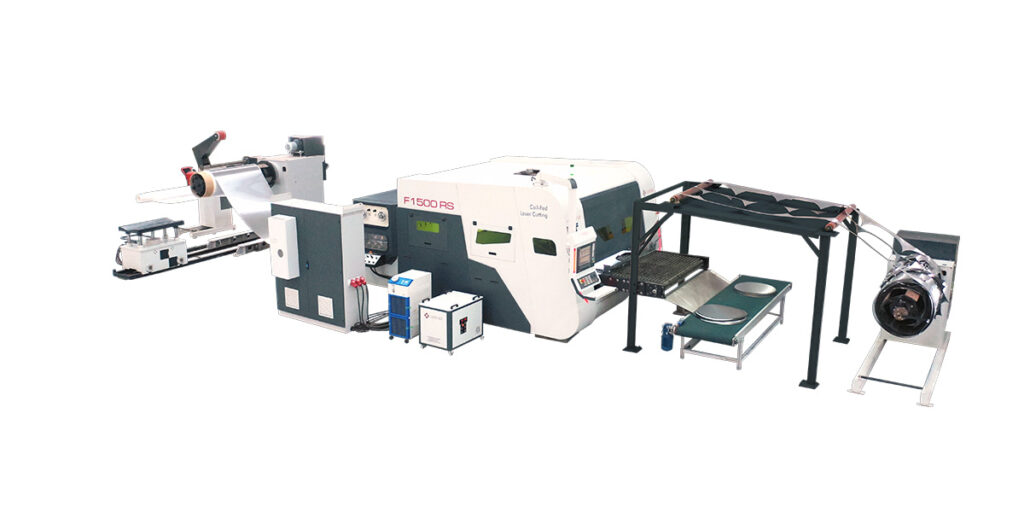

Feeding system for sheet metal coil in laser cutting

Machine used for robotic unloading in laser cuttingęciu laserowym

Gantry crane unloading system used in laser cutting from coil

Bending arm used in laser cutting from coil

| AVAILABLE MODELS | LR SERIES | GP SERIES | MR SERIES | HR SERIES |

| LASER CUTTING TABLE | 1500mm x 2000mm | 1550mm x 2000mm | 1550mm x 2000 mm | 1550mm x 2000mm |

| DISMANTLING CAPACITY | 5t / Opcjonalne do 10t | 2t / Opcjonalnie do 25t | 15t / Opcjonalnie do 30t | 15t / Opcjonalnie do 30t |

| WIDTH SETTINGS | 400mm – 1550mm | 400mm – 1550mm | 400mm – 1550 mm | 400mm – 1550mm |

| MATERIAL THICKNESS | 0.3mm – 1.2mm | 0.4mm – 2mm | 0.5mm – 4mm | 1mm – 6mm |

| LASER POWER | ||||

| 1kW – 10 kW | 1500W, 2000W, 3000W, 4000W, 6000W | |||

| 2kW – 10 kW | 2000W, 3000W, 4000W, 5000W, 6000W | |||

| LASER CUTTING | ||||

| CNC Model | Fanuc / Siemens | |||

| Cutting head | Precitec, Lightcutter / Procutter | |||

| Laser source | Disk laser or Fiber laser | |||

| Laser safety | EU safety standards | |||

| Sheet metal detection | Laser sensor / camera | |||

| Measurement accuracy | Integrated guide rail with encoder | |||

| Laser cutting table | 1550mm x 2000mm (Standard) / Table customization options are available | |||

| Loading cart | ||||

| Load capacity | 12.000kg (Optional Max. up to 30.000kg) | |||

| Coil external average | 1300mm (Optional; Max. 2200mm) | |||

| Decoiler | ||||

| Decoiler capacity (min – max) | 1000 kg – 30000 kg | |||

| Belt width Capacity | 20mm – 2000mm | |||

| Speed control system | Adjustable drum speed | |||

| Coil protector | Extendable arm | |||

| Servo feeder with straightener | ||||

| Control | Siemens or Bosh Rextroth | |||

| Width setting (min. – max.) |

20mm – 2000mm |

|||

| Thickness range (min. – max.) | 0.3 – 2mm (Optional: Max. 10mm) | |||

| Thickness adjustment |

Screw mechanism (optional; servo-driven) |

|||

| Width adjustment | Screw mechanism (optional; servo-driven) | |||

| Scrap recycler | ||||

| Belt width capacity (max.) |

2000mm |

|||

| Speed control system | Adjustable speed | |||

Contact Us

Maintenance services