How does laser cleaning work?

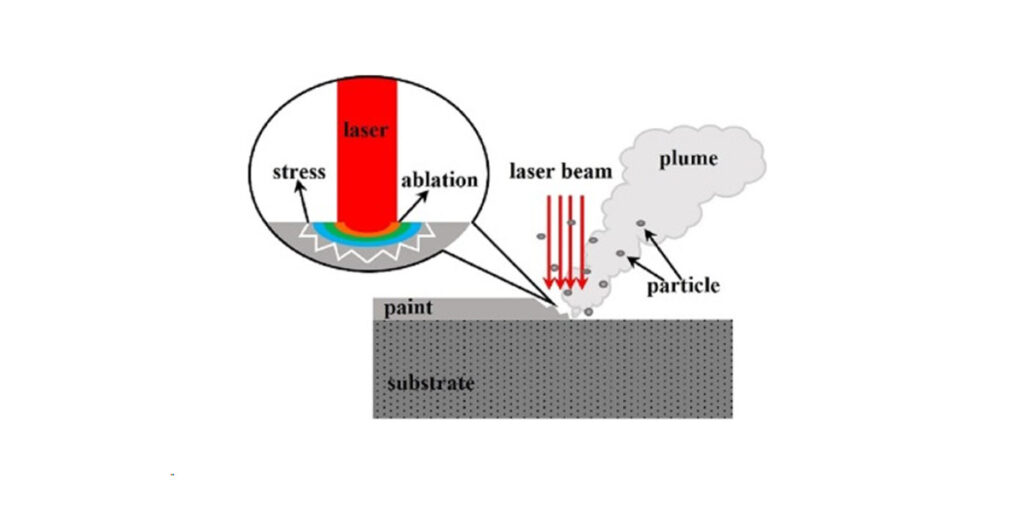

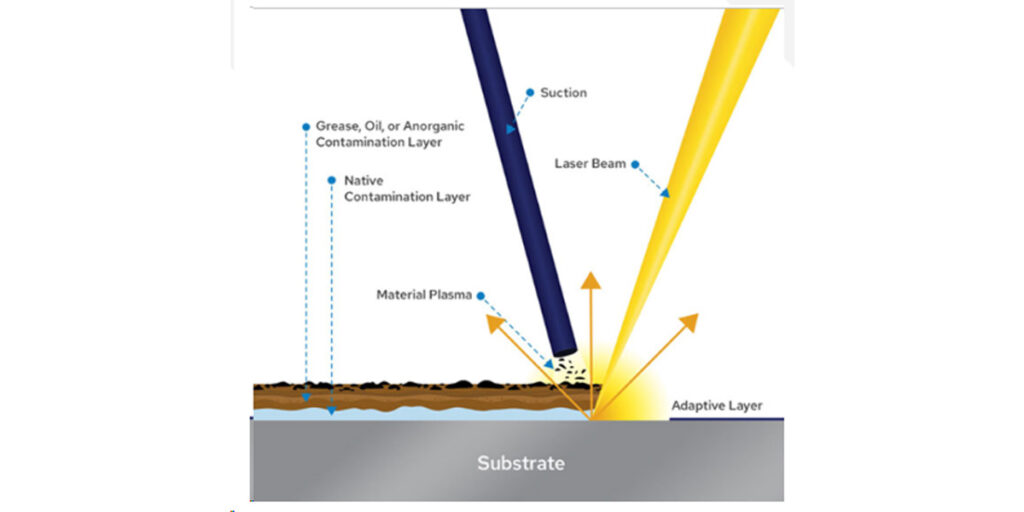

Laser cleaning technology involves sending pulses of nanosecond laser light toward a surface

When interacting with contaminants that absorb the laser light, the contaminants or coating particles turn into a gas, or the interaction pressure releases the particles from the surface