How does laser cleaning work?

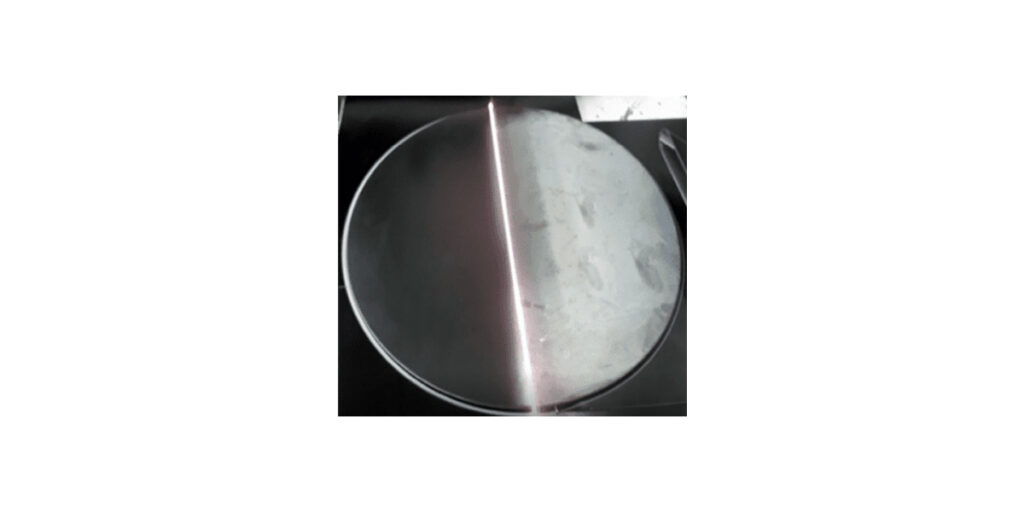

Laser cleaning is an exciting new laser process in which dirt, debris or contaminants (such as carbon, silicone and rubber) are removed from the surface of a material using laser radiation. Not only is it a low-cost solution, it is also the most environmentally friendly technique compared to conventional cleaning processes, which are widely used in many industries around the world.

Laser coating removal is an ablative process in which laser energy is focused and absorbed by the surface, resulting in vaporization of the coating with minimal impact on the underlying level. The process can be applied to a variety of materials, including metal, plastics, composites, as well as glass.

Laser types

FIBER LASER

Fiber lasers are highly effective in cleaning thanks to advanced technology.

Pulsed laser beams with a wavelength of 1064 nm enable shorter process times and lower operating costs.

DIODE LASER

Diode lasers provide excellent quality at laser powers of up to many kilowatts.

Stable processes through integration provide active control of laser power for the highest precision and repeatable results.

CO2 LASER

CO2 lasers are advantageous when it comes to material types, with the flexibility to adapt to a wider range of materials.

With a wavelength of 10.6 µm (the far end of the infrared range), CO2 lasers are ideal for cleaning the surface of organic materials.

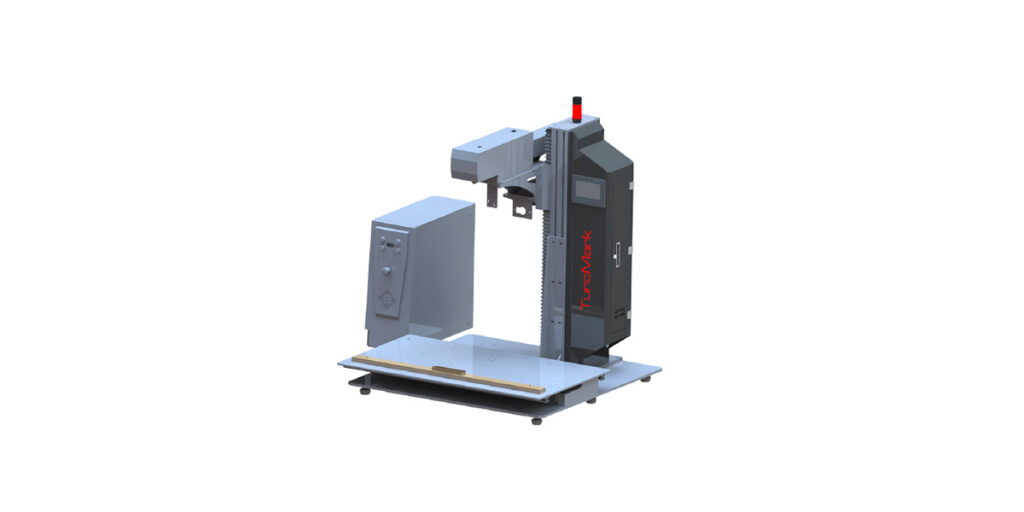

Models

6 – axis robot

Custom design

Desktop design