NOVATEC machines provide a complete production solution for short tube manufacturers.

The HVAC market (products for heating, ventilation and air conditioning) was worth just under 7 billion zlotys in 2019 (PMR, 2019). Despite the high level of competition in this market, in each of its segments we have domestic manufacturers of chimney systems, fireplace inserts, ventilation systems, whose products reach customers throughout Europe and beyond.

Increasing quality requirements, regulations on fireplace fuels, the ubiquitous automation and digitalization of HVAC systems, and high competition in the market makes it a very rapidly growing manufacturing sector in Poland from the side of production and use of the latest technologies.

For 18 years, VENTOR has been successively helping HVAC manufacturing companies to implement the latest technologies, most importantly the production of short pipes – from a coil of sheet metal to a finished chimney pipe. The implementation of laser pipe welding systems is chosen by both the largest tycoons and companies wishing to gain a significant competitive advantage by implementing the solutions we offer.

Today we are pleased to introduce NOVATEC as a complement to our offer for manufacturers in the HVAC industry. Machines from this Italian manufacturer can be found in the production facilities of industry giants in Europe, the USA, North America, Russia, India and the Southeast.

NOVATEC machines are a complete production solution for short pipe manufacturers including the following:

Novatec BDM pipe end processing machine – Male / Female (M/F) . Diameter from 60 to 400 mm. Thickness from 0.4 to 1 mm. Materials: stainless steel, galvanized steel. Loading / unloading of pipes: manual or automatic. The machine can be in horizontal or vertical loading version.

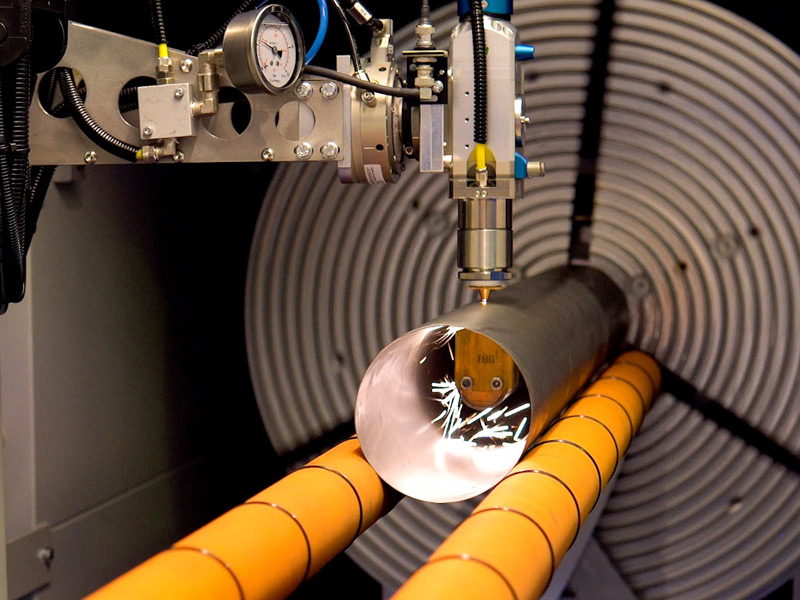

Novatec NovaCut – machine for laser cutting and cutting of pipes. Diameter range from 60 to 700 mm. Pipe length from 1000 to 2000 mm. Diameter from 80 to 150 mm. ( In the LARGE version the diameter even up to 1000mm). Thickness from 0,4 to 3 mm. The pipe is mounted on a universal mounting mandrel and moves relative to the stationary laser head. The solution is ideal for preparing pipes for welded bends, tees, etc.

Novatec RDT – machine for flanging of pipe ends. Diameter range from 60 to 900 mm. Thickness from 0.4 to 1 mm. Materials: aisi stainless steel. Mild steel 300400 galva. Manual loading / unloading.

Novatec MTE – tee pulling machine. Starting from a pre-cut pipe (laser plasma), the machine automatically pulls out the tee. Each diameter has a dedicated tool and the principle of operation is similar to the hydraulic press – in this case we do not press, but pull up the tee. Diameter from 60 to 400 mm. Thickness from 0.4 to 1 mm. Neck shape: round, rectangular.

Novatec MBP – laser welding of elbows. The machine supports 45 and 90 degree versions. Manual loading of parts. TIG welding . Diameters from 60 to 400mm, each diameter has dedicated clamping fixtures.

Novatec CM1 – welding of elbows from 2 stamped parts. A very popular method of manufacturing elbows in Poland. Diameters from 80 to 315 mm. Angles 30 ° / 45 ° / 90. Resistance welding technology with electrode wire. Thickness of 0.6 mm. Production rate: 15 seconds per elbow.

Novatec RWB – Insulation of pipes with double walls, filling with mineral wool between two pipes, which means that the mineral wool material is supplied in fibers between the inner and outer pipe. Material: mineral wool made of natural fibers with a density of about 150,200 kg / m 3. The RWB machine series includes versions for filling straight pipes, elbows, tees or custom elements.

The above summary of the main machines produced by Novatec shows the scope of production that can be simplified, accelerated and improved by implementing the solutions described above. The joining technologies we can install on Novatec machines are Laser, Plasma, TIG, MAG. Together with Novatec, we can equip your production with any of the short pipe processes from sheet coil to finished system with elbows, tees, pipes with male and female ends and double pipes with wool insulation.

A very important point to add is that each Novatec production machine can operate both as a stand-alone and operator-operated unit, but can also be integrated into, for example, the Weil Technology Flexistar short pipe production system that precedes it, or robotized to automate the loading and unloading of a given process.

Novatec Engineering is located in the Como region of northern Italy. It was founded in 2012 by HVAC manufacturing practitioners. The company has its own design office where Novatec-branded machines are developed, as well as its own manufacturing and assembly department. The goal of the Novatec brand is to provide solutions dedicated to HVAC production and to develop technologies based on close cooperation in the letters of the industry worldwide.

Novatec brand equipment is available in Poland exclusively from VENTOR. Ventor also provides service of Novatec equipment and has a warehouse of Novatec brand spare parts in Poland.