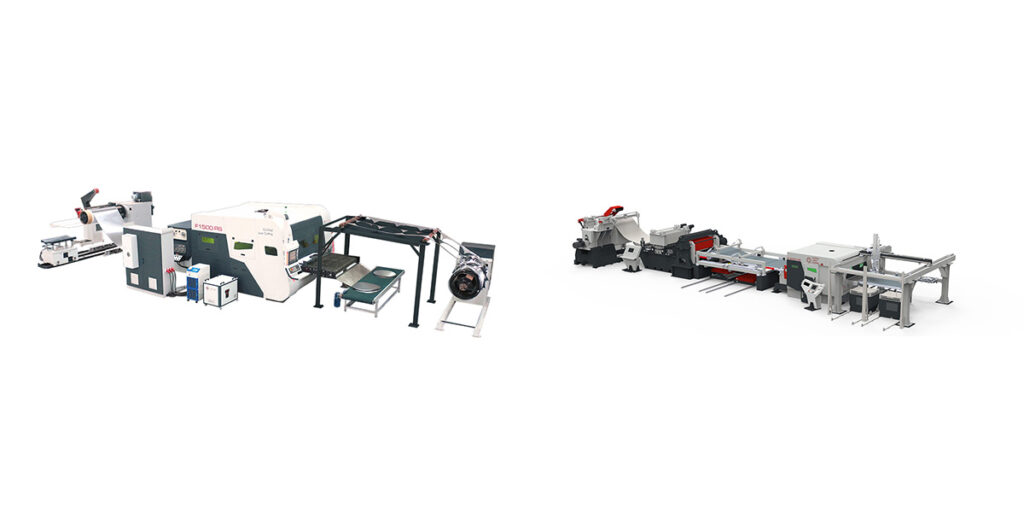

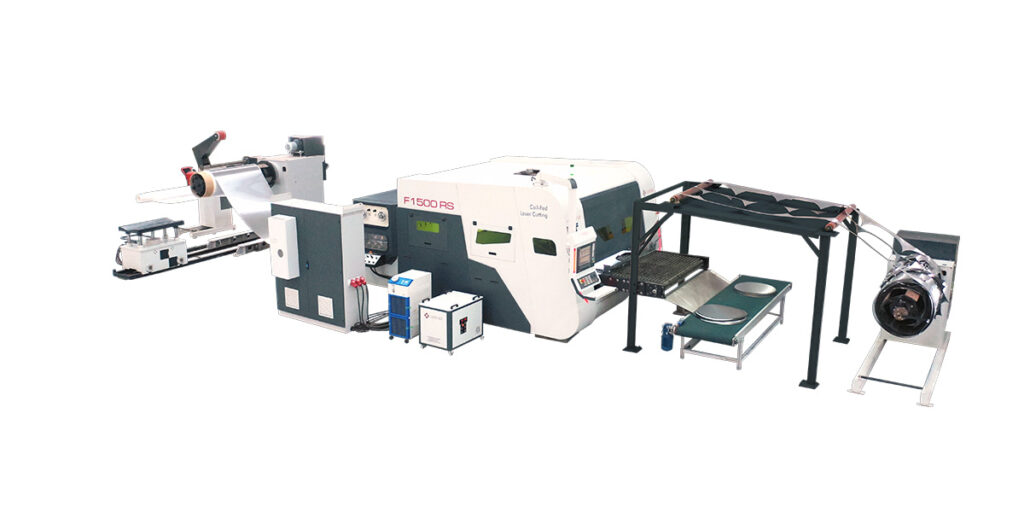

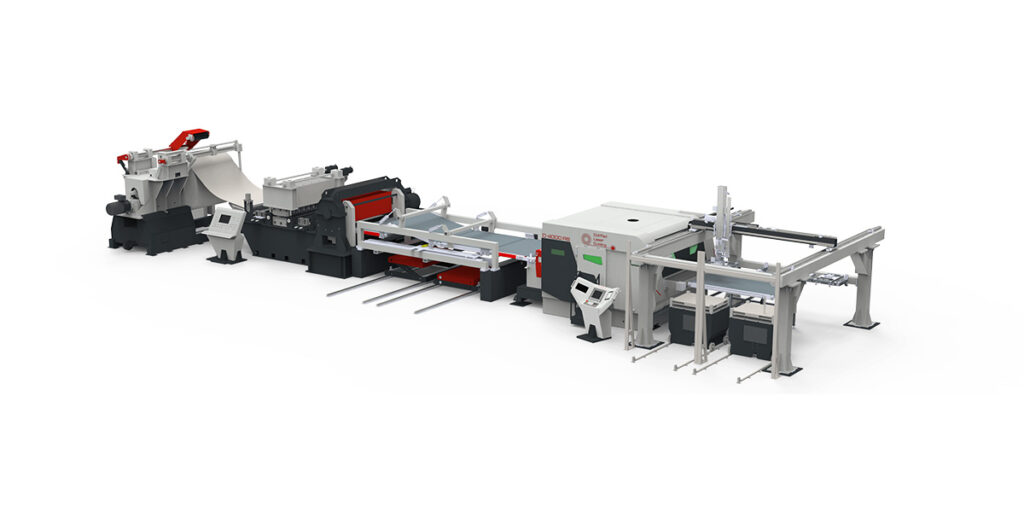

The 2D laser cutting system is an advanced technology used for precision cutting of flat materials.

Laser cutting in the ventilation industry is an advanced technology that makes it possible to precisely and efficiently cut ventilation system components from various materials such as galvanized steel, aluminum and plastics. The technology is crucial for the production of high-quality air ducts, housings, grilles and other components of HVAC (Heating, Ventilation, and Air Conditioning) systems.

The main advantages of laser cutting in the ventilation industry are:

- Precision: It enables the precise cutting of complex shapes and patterns, which is essential to ensure the tightness and functionality of ventilation systems.

- Speed: Laser cutting is much faster than traditional methods, increasing production efficiency and reducing lead times.

- High edge quality: Provides smooth and clean edges, eliminating the need for additional machining and reducing production costs.

- Flexibility: Allows the process to be easily adapted to different materials and designs, which is crucial for producing diverse ventilation components.

- Waste minimization: Precision laser cutting minimizes material waste, resulting in cost savings and environmental benefits.

Laser cutting is used in the production of ventilation components such as ducts, elbows, tees, silencers and grilles. Thanks to this technology, manufacturers can provide components that meet the highest standards of quality, performance and durability, helping to create efficient and reliable HVAC systems.