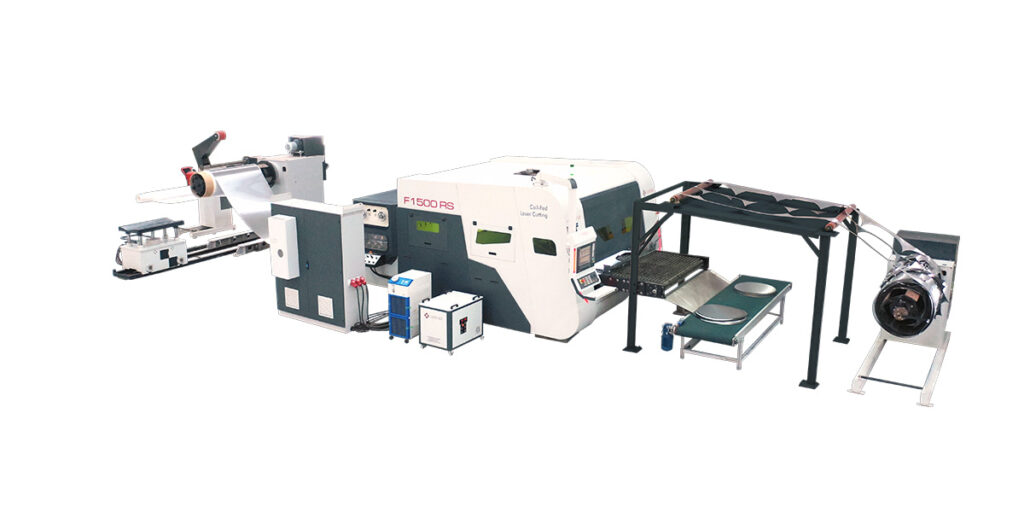

The 2D laser cutting system is an advanced technology used for precision cutting of flat materials.

Laser cutting for steel structures is a state-of-the-art technology that enables precise, fast and efficient cutting of steel components used in construction and engineering. By using a concentrated laser beam, the process ensures exceptional accuracy and quality of cutting, which is crucial for complex construction projects.

The main advantages of laser cutting in steel structures are:

- Precision: Enables accurate cutting of complex shapes and patterns, which is essential to ensure the fit and strength of structures.

- High edge quality: Provides smooth, clean edges without the need for additional machining, reducing production time and costs.

- Speed: Laser cutting is much faster than traditional cutting methods, speeding up the production process and projects.

- Flexibility: Allows easy adaptation to different thicknesses and types of steel, which is key in a variety of structural applications.

- Waste minimization: Precision cutting minimizes material waste, resulting in cost savings and environmental benefits.

Laser cutting is widely used in the production of steel structural components such as beams, columns, plates, brackets and other components. With this technology, companies can carry out complex construction and engineering projects, ensuring the high quality, durability and reliability of their structures.