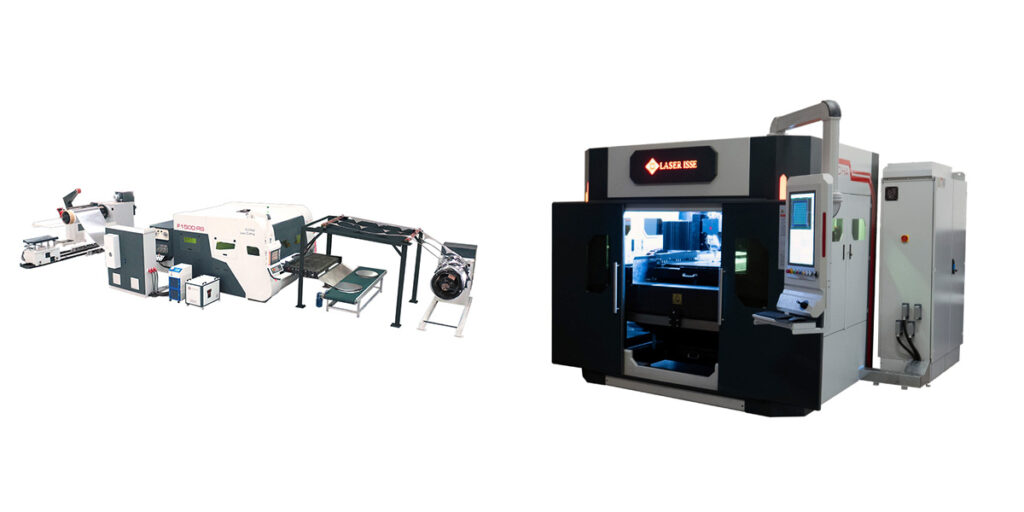

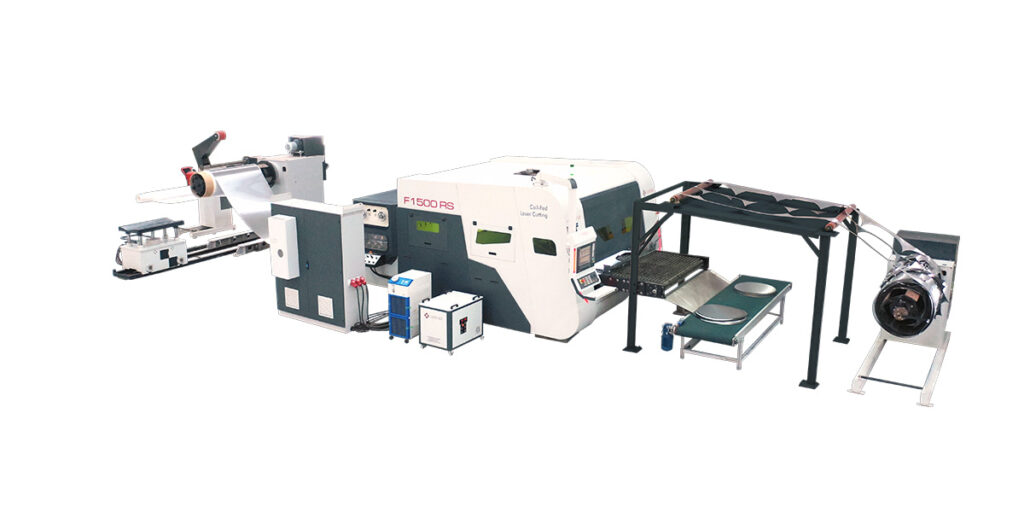

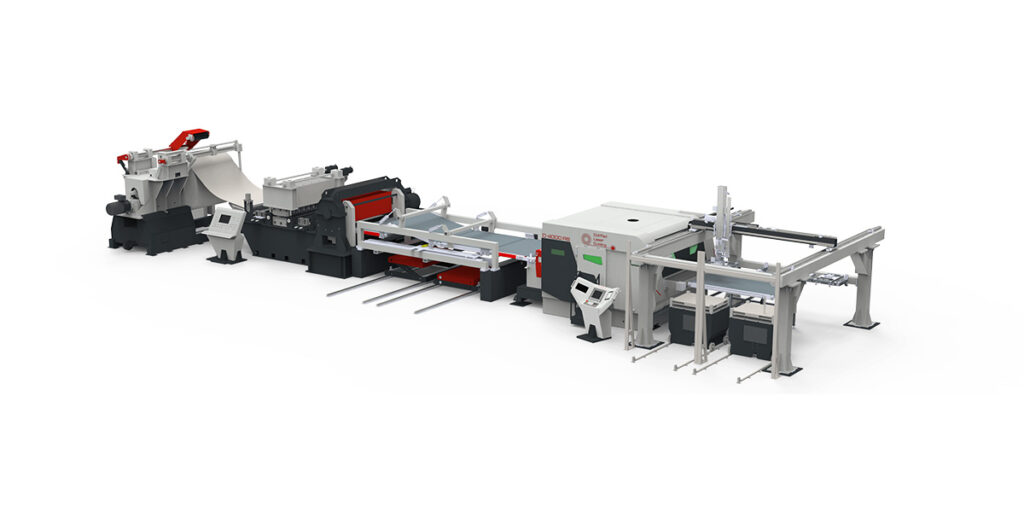

The 2D laser cutting system is an advanced technology used for precision cutting of flat materials.

Laser cutting in the sheet metal forming and cutting industry is an advanced metalworking technology that enables precise, fast and efficient cutting of various shapes from sheet metal.

The technique uses a concentrated beam of light – a laser to cut materials, resulting in smooth and clean edges and minimizing thermal distortion. In the sheet metal forming industry, laser cutting is particularly valued for its ability to cut intricate and precise patterns from a variety of materials, such as steel, aluminum, copper and metal alloys.

The process is crucial for producing high-precision components used in industries such as automotive, home appliances, aerospace, construction and electronics.

The use of laser cutting makes it possible to:

- Increase production efficiency through cutting speed and precision.

- Reduction of material losses by optimizing the cutting process.

- Production flexibility to easily adapt to different designs and customer specifications.

- Increased quality of final products due to precise and clean laser cut edges.

As a result, laser cutting in the sheet metal forming and cutting industry is an indispensable tool that supports innovation, productivity and competitiveness in modern manufacturing processes.