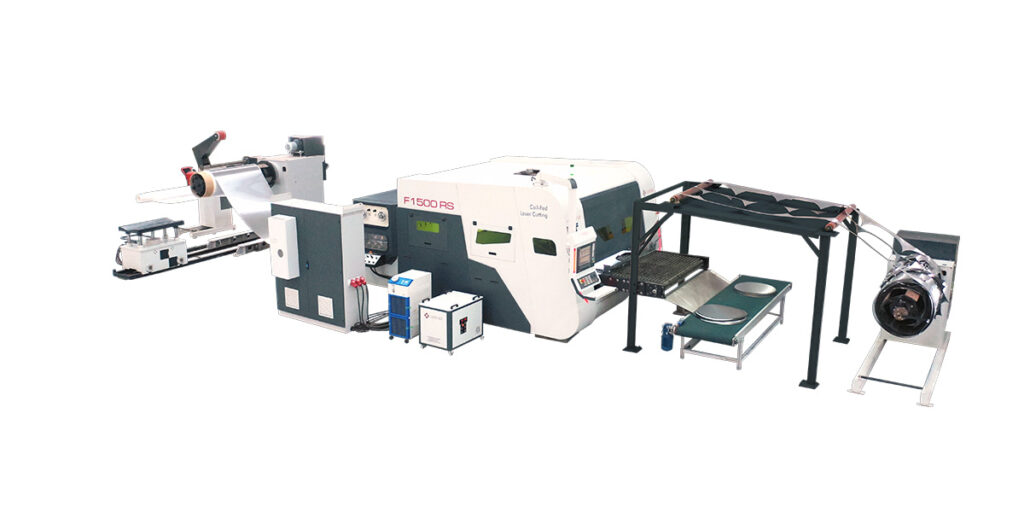

The high accuracy laser cutting system is an advanced technology designed to precisely cut intricate shapes from a variety of materials such as metal, plastic, ceramics and composites.

Laser cutting in pipe machining is an advanced technology that can precisely and quickly cut complex shapes and holes in pipes made of various materials such as steel, aluminum, titanium and plastics. The technology is crucial in many industries, including automotive, aerospace, construction and medical.

The main advantages of laser cutting in pipe processing are:

- High precision: Allows accurate cutting of complex shapes and patterns, which is essential for components requiring high accuracy.

- Cleanliness and edge quality: Provides smooth, clean edges, eliminating the need for additional machining and reducing production time and costs.

- Speed: The laser cutting process is much faster than traditional methods, increasing production efficiency and reducing lead times.

- Flexibility: Allows easy adaptation to different pipe diameters and thicknesses, which is key for a wide range of industrial applications.

- Waste minimization: Precision cutting minimizes material waste, resulting in cost savings and environmental benefits.

Laser cutting is used in the production of various tubular components such as manifolds, frames, exhaust systems, hydraulic systems and other structures. With this technology, manufacturers can realize complex designs with high accuracy and efficiency, helping to create more advanced and durable products.