Laser cleaning of tire molds has become a breakthrough technology in the tire industry.

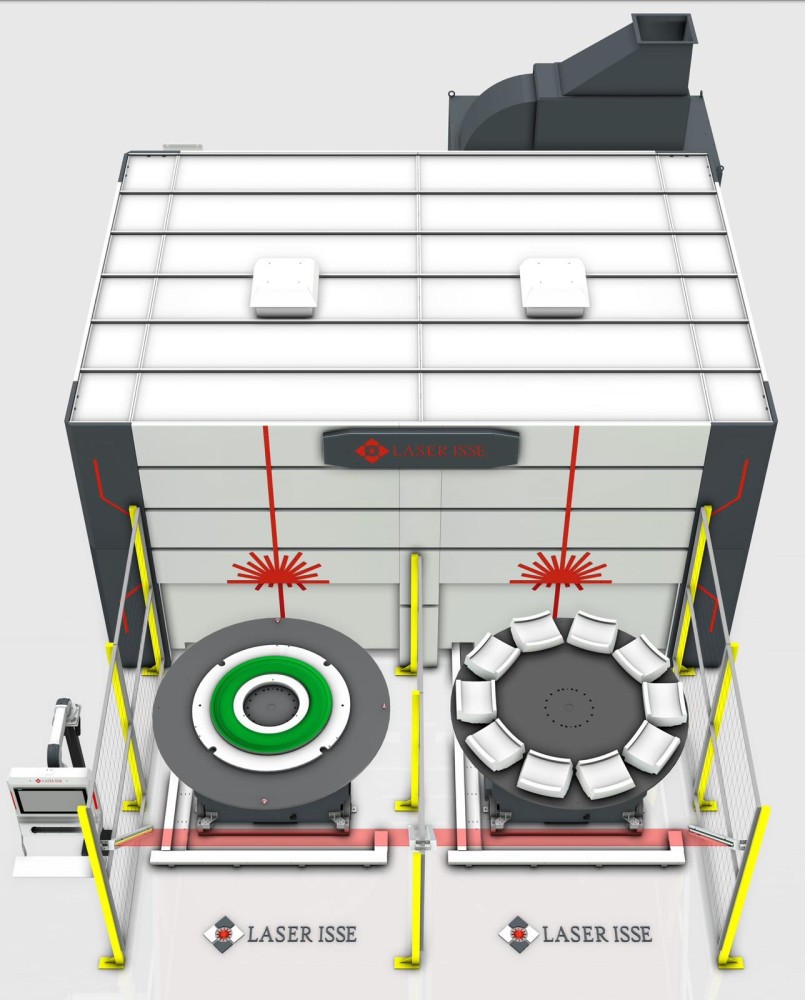

Laser cleaning of tire molds – TWIN STATION LASER CLEANING CELL

Laser cleaning of tire molds has become a breakthrough technology in the tire industry. This innovative method not only increases the precision and efficiency of mold cleaning, but also provides an environmentally friendly approach. The importance of maintaining clean tire molds cannot be overstated, as it directly affects the quality and durability of tires. The laser cleaning technique offers a non-invasive, automated solution that solves the limitations of traditional cleaning methods.

Advantages of Laser Tire Mold Cleaning

- Surface integrity: Ensures no damage to the mold surface.

- Precision: Enables highly accurate cleaning, reaching intricate mold details.

- Efficiency: Much faster cleaning cycles compared to conventional methods.

- Environmental impact: Eliminates the need for chemicals and reduces waste, making this technology environmentally friendly.

- Minimal emissions: Laser cleaning generates significantly lower noise and dust emissions compared to conventional sandblasting methods, helping to improve working conditions.

- Low operating costs: Low energy consumption, no need to purchase consumables and minimal waste disposal costs ensure significantly lower operating costs.

- Safety: The laser cleaning process eliminates the risks associated with the emission of hazardous dust and chemicals, making it safer for workers and the environment.

- Temperature flexibility: The process works effectively on both cold and hot molds, eliminating the need to heat the mold outside the press, as is the case with other cleaning methods.

- Reduction in carbon footprint: Laser cleaning uses less energy and generates fewer CO2 emissions compared to methods such as dry ice cleaning, helping to reduce the carbon footprint.

- Longer mold life: The lack of mechanical wear and invasive action of cleaning materials translates into a longer life for tire molds, allowing them to be used longer without the need for frequent replacement and maintenance.

These benefits contribute to increased productivity, cost savings and improved product quality in the tire manufacturing process.

By loading this video, you agree to the privacy policy of Youtube.

Comparison of Laser Cleaning with Traditional Methods

Traditional tire mold cleaning methods, such as dry ice cleaning, sandblasting and chemical cleaning, are widely used, but have many disadvantages:

- Dry ice cleaning: Effective, but can be invasive and damage the mold surface over time.

- Sandblasting: Highly invasive, leading to significant mold wear.

- Chemical cleaning: Requires the use of hazardous chemicals that pose environmental and safety risks.

In contrast to these methods, laser cleaning is non-invasive, safe and offers higher precision, making it the preferred option for maintaining the integrity of tire molds. After using the laser to clean molds, there is no maintenance required.

Applications in the Tire Industry

Laser cleaning technology is widely used for various components in tire molds, including:

- Tire mold segments: Cleaning intricate patterns and designs on mold segments, ensuring their clear and precise appearance. By precisely removing contaminants, mold segments retain their details, resulting in the quality of the tires produced.

- Sidewall plates: Providing smooth, residue-free surfaces for sidewalls. Laser cleaning maintains the high quality finish of tire sidewalls, which is critical to the aesthetics and functionality of the final product.

- Spring-loaded vents: Laser cleaning is particularly effective at removing contaminants from delicate structures such as spring vents. This keeps these vents clean and effective, resulting in better air evacuation and higher tire quality.

- Workflow: Integrate into existing production flows, increasing overall efficiency. Laser technology can be easily integrated into existing production processes, minimizing downtime and optimizing mold cleaning time. This makes the entire tire manufacturing process more efficient and cost-effective.

- Complex patterns and details: laser cleaning excels at removing contaminants from the most complex patterns and details on molds, which is difficult to achieve with traditional methods. This results in better visual and technical quality for tires produced using clean molds.

- Extended mold life: Thanks to the non-invasive nature of laser cleaning, tire molds are not subject to mechanical wear, which significantly extends their life and reduces the costs associated with frequent mold replacement.

All these applications of laser cleaning technology contribute to the production of high-quality tires, while increasing efficiency and reducing operating costs in the tire industry.

Step by Step Laser Cleaning Process – TWIN STATION LASER CLEANING CELL from Laser ISSE.

The laser cleaning process can be divided into several steps:

- Loading: The tire molds are loaded onto the conveyor system.

- Cleaning: Laser beams clean the molds, removing contaminants without physical contact.

- Unloading: Clean molds are unloaded and ready for reuse.

- Automation: Advanced robotic systems and PLC control facilitate a fully automated cleaning cycle.

Challenges and Solutions in Laser Cleaning

While laser cleaning of tire molds offers numerous advantages, it also poses some challenges:

- Initial Investment: High initial costs can be a barrier, but the long-term savings often justify the expense.

- Technical Expertise Required: Requires skilled operators and regular training to ensure optimal performance.

- Maintenance: Regular maintenance of laser equipment is critical to avoid downtime.

Economic Aspects of Laser Cleaning

Investing in laser cleaning systems for tire molds can be profitable in the long run. Key economic aspects include:

- Cost-Benefit Analysis: Significant reduction in operating costs due to lower maintenance and material costs.

- Return on Investment: Rapid return on investment (ROI) through increased productivity and reduced downtime.

These economic benefits make laser cleaning a viable option for tire manufacturers looking to optimize their processes.

Environmental Impact of Laser Cleaning

Laser cleaning of tire molds is an environmentally friendly alternative to traditional methods. Key environmental benefits include:

- Reduced Use of Chemicals: Eliminates the need to use hazardous chemicals, reducing environmental pollution.

- Minimization of Waste: Produces minimal waste compared to conventional methods.

- Regulatory Compliance: Meets stringent environmental regulations, ensuring sustainable operations.

Integration with Production Systems

Laser cleaning technology can be integrated with manufacturing management systems (MES) to improve process control and monitoring. Key benefits of integration include:

- MES Compatibility: Seamless integration with existing MES systems for real-time data tracking.

- Data Monitoring: Continuous monitoring of cleaning processes to ensure optimal performance.

- Systems Interoperability: Compatibility with other industrial systems for comprehensive process management.

Contact Us