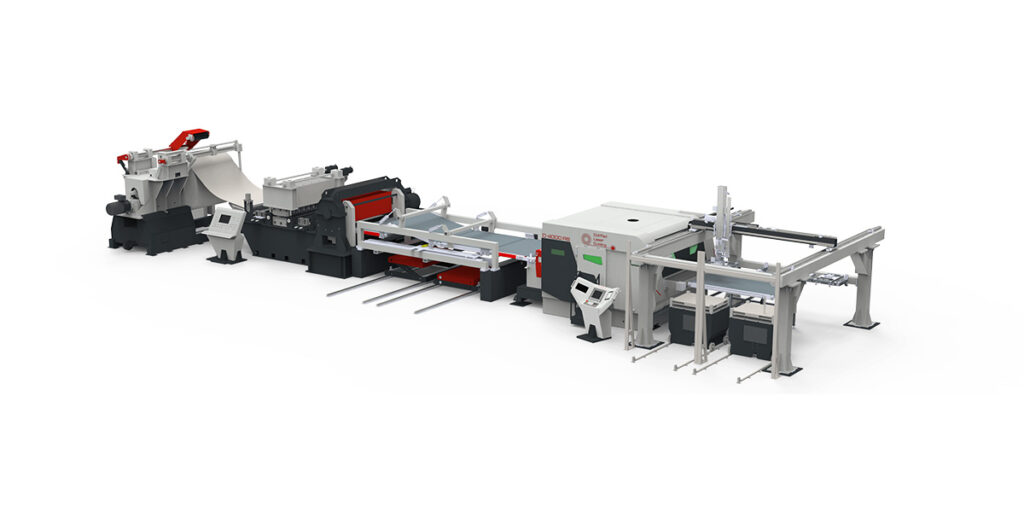

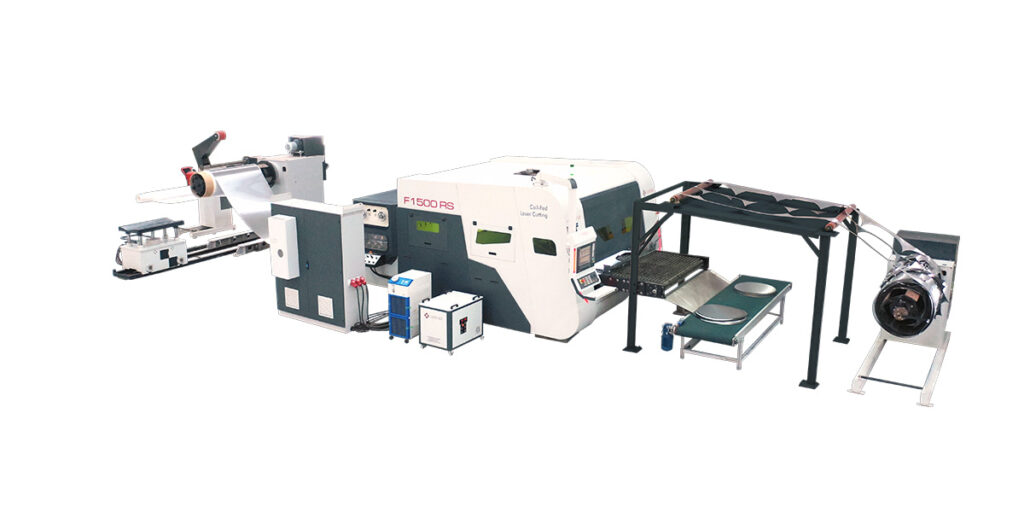

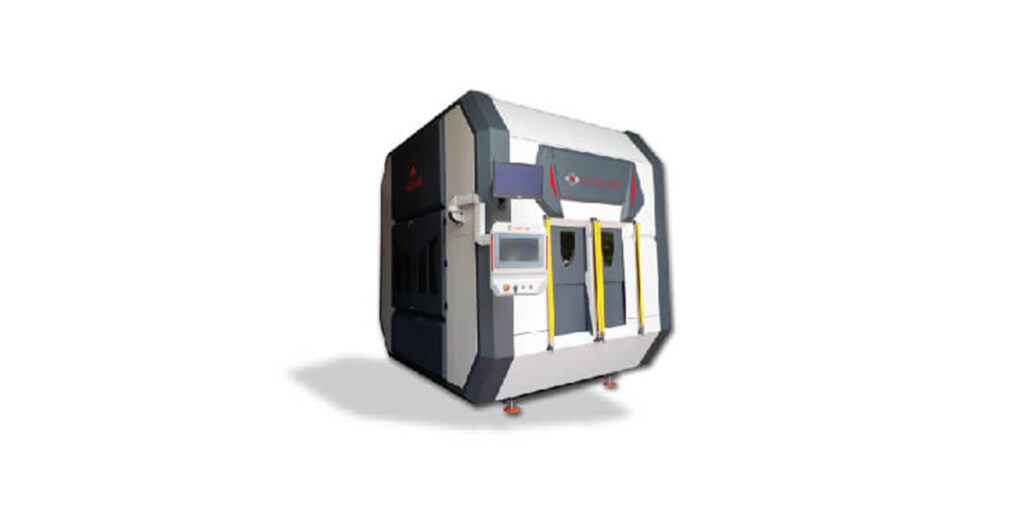

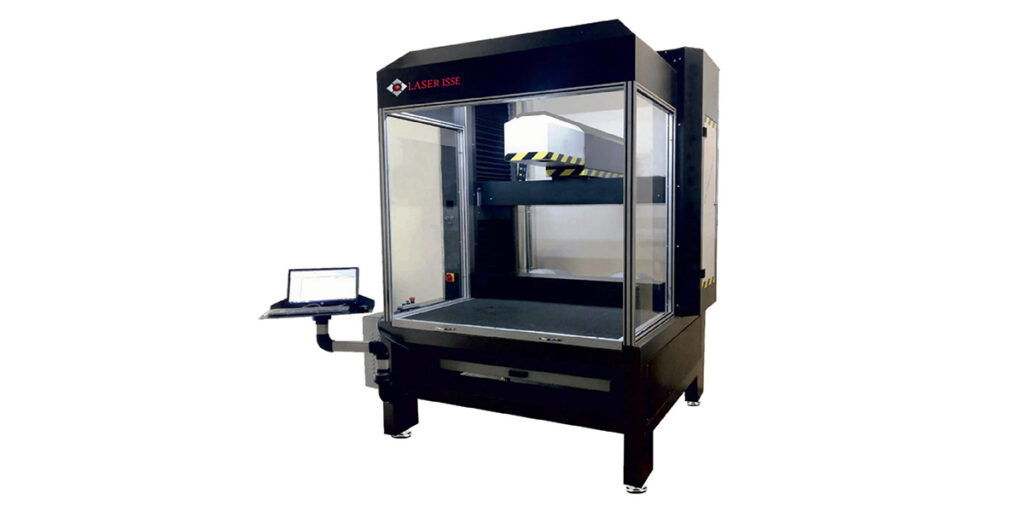

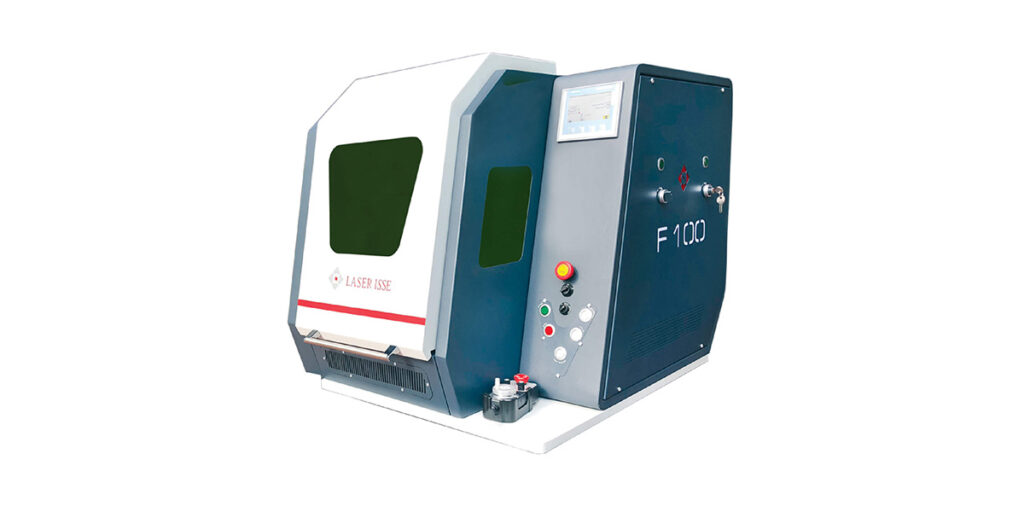

The production lines enable the cutting of a wide variety of materials, such as metals, plastics, wood and composites. With advanced computer control and full automation capabilities, they ensure high quality, repeatability and minimal waste.

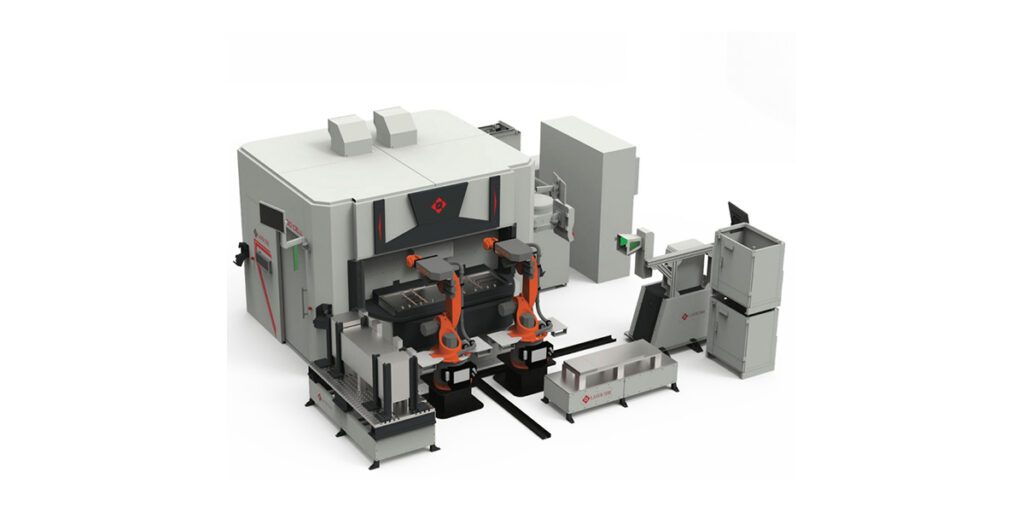

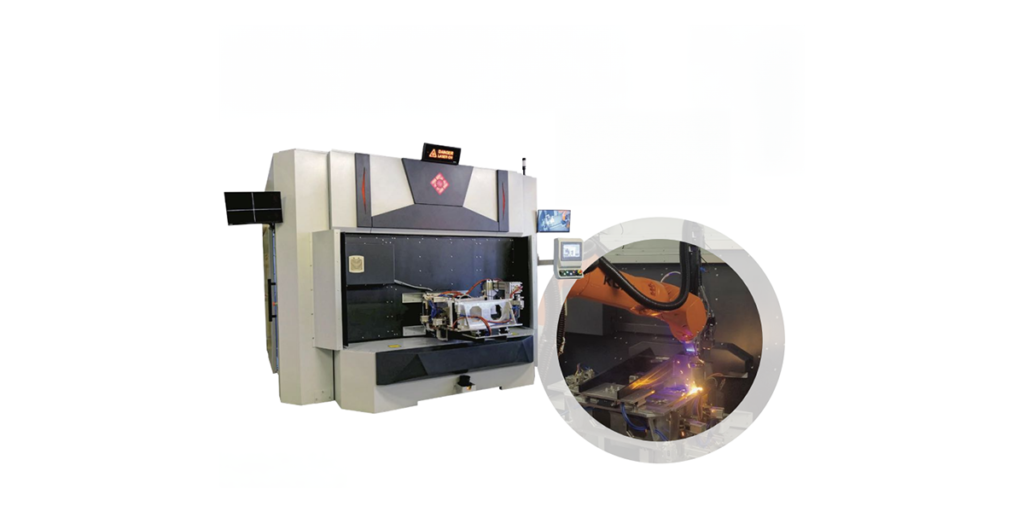

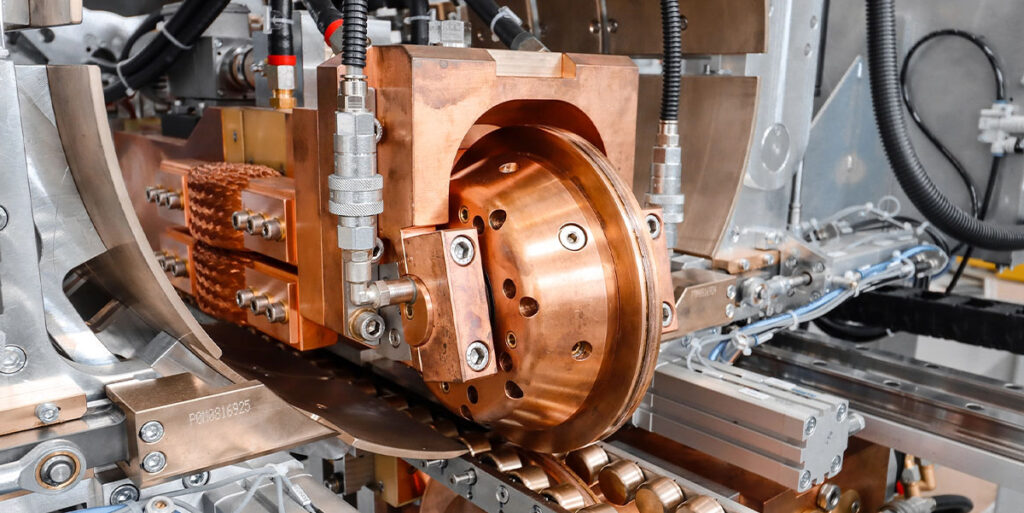

In order to drastically reduce design effort, run time and assembly costs, Weil technology has developed a flexible laser cell that opens up new perspectives in component design and production. Together with an integrated and additional adaptive handling system, it is possible to assemble entire pressed sheet assemblies (3D) in a single machine (one clamping – CutFusion process). The goal of the innovation is to improve production processes, eliminate transport times by combining work sequences, improve part quality and noticeable cost savings through the use of laser technology.