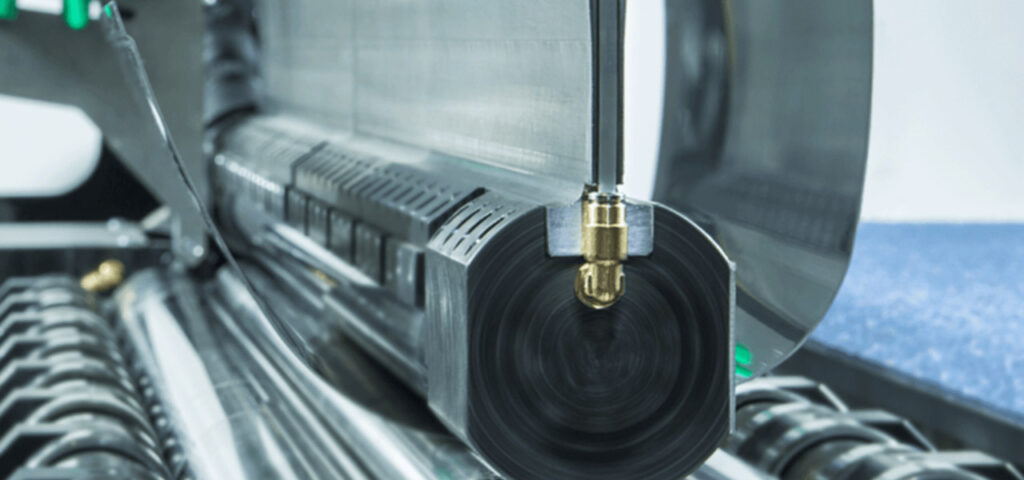

Scissor technology for cutting and slitting hydroformed and bent pipes.

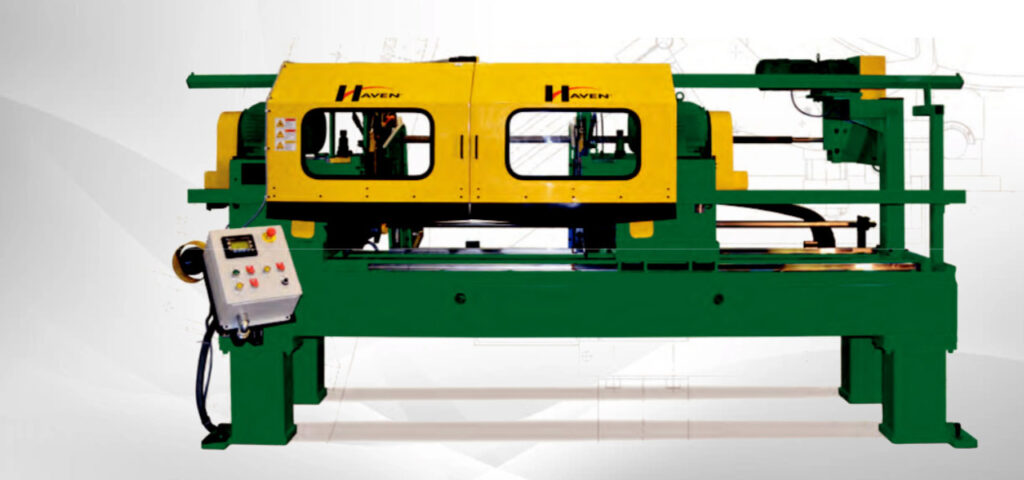

Pipe and profile processing machines – we provide comprehensive technology in the field of pipe and profile processing. We specialize in the process of cutting, coiling and laser welding of pipe starting from fi 60 diameter. Thus, our solutions are used in many production areas such as the chimney and ventilation industry. We offer multifaceted and precise pipe and profile processing technology solutions for the automotive, energy, furniture or white goods industries. For laser cutting of pipes and profiles, our specialists use modern machines that allow processing with high accuracy and the required precision. We are able to guarantee the preservation of smooth edges and a clean surface without scratches or chips.