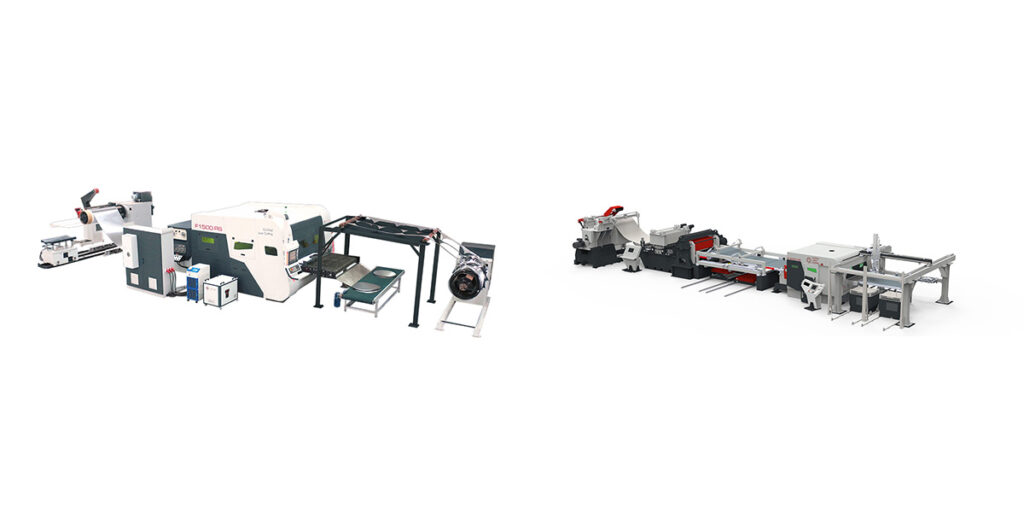

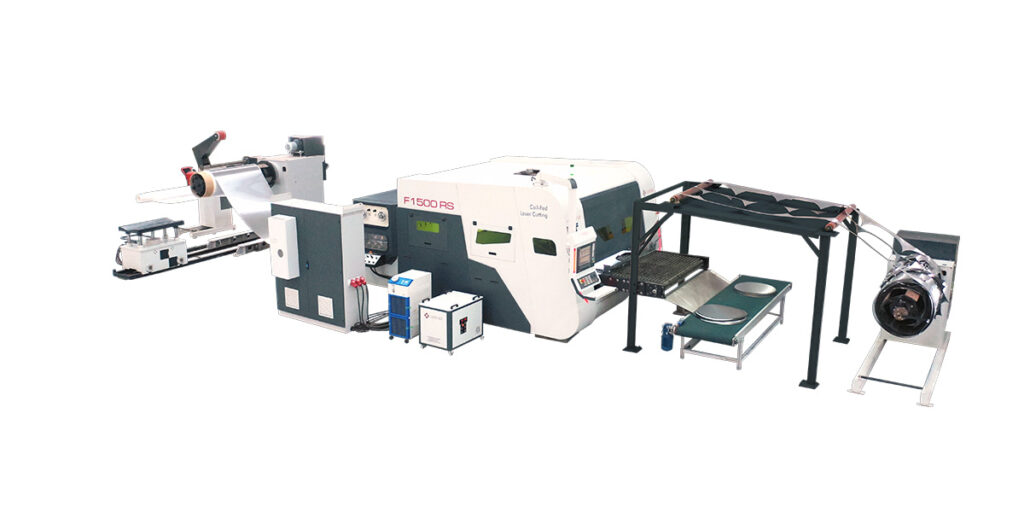

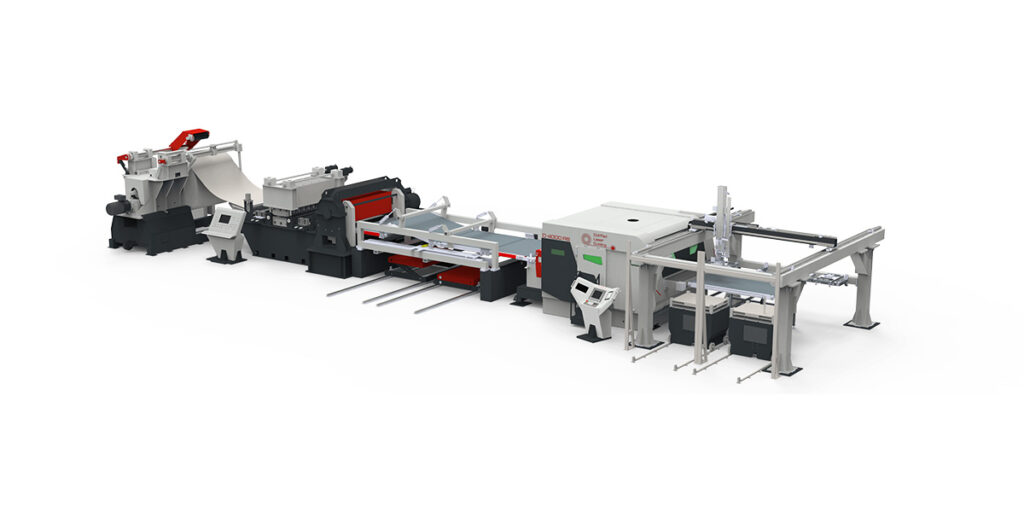

The high accuracy laser cutting system is an advanced technology designed to precisely cut intricate shapes from a variety of materials such as metal, plastic, ceramics and composites.

Laser cutting in photovoltaics is an advanced technology that enables precise and efficient cutting and machining of components used in solar panels. This technology is crucial for the production of modern and efficient photovoltaic panels, where accuracy and minimal material damage are essential.

The main advantages of laser cutting in photovoltaics are:

- Precision: Allows accurate cutting of complex shapes and patterns, which is crucial for optimal solar cell placement.

- Minimal heat damage: The concentrated laser beam reduces the impact of heat on surrounding materials, which is important for delicate photovoltaic components.

- Speed: Laser cutting is fast, increasing production efficiency and reducing lead times.

- Versatility: Allows cutting of various materials used in solar panels, such as silicon, glass, metals and plastics.

- Process cleanliness: Provides clean and smooth edges, which eliminates the need for additional processing and minimizes contamination.

Laser cutting is used in various stages of photovoltaic panel production, from cutting solar cells to precision cutting of glass covers. With this technology, solar panel manufacturers can create more efficient and durable products that meet the highest standards of quality and energy efficiency.