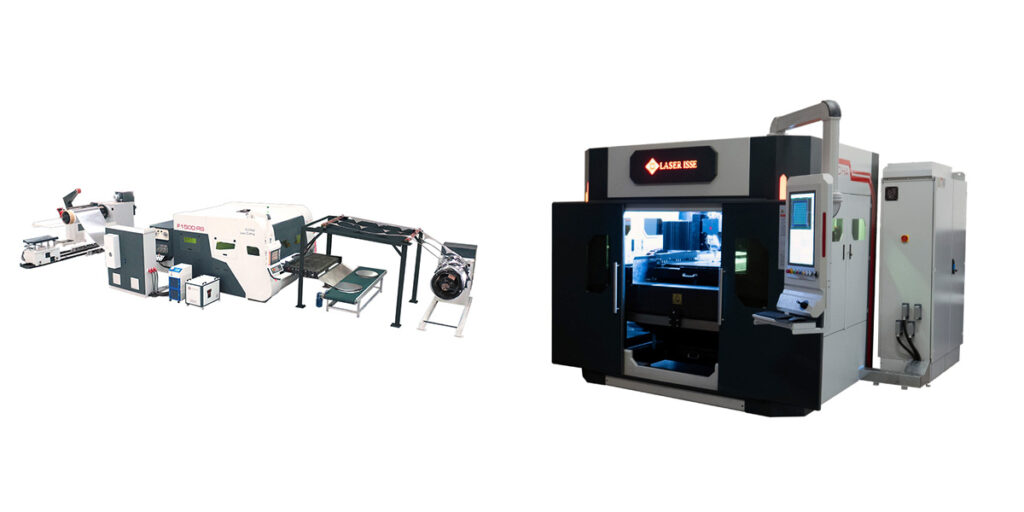

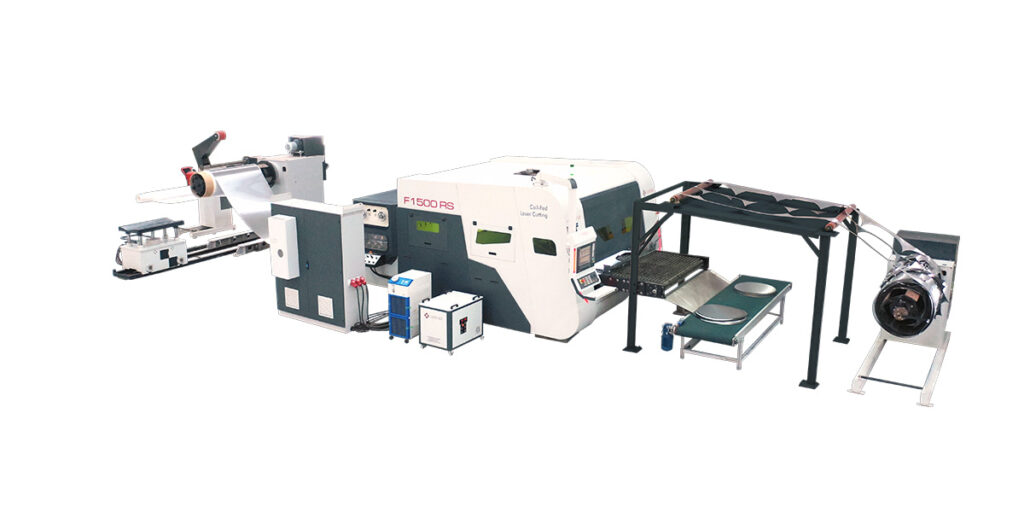

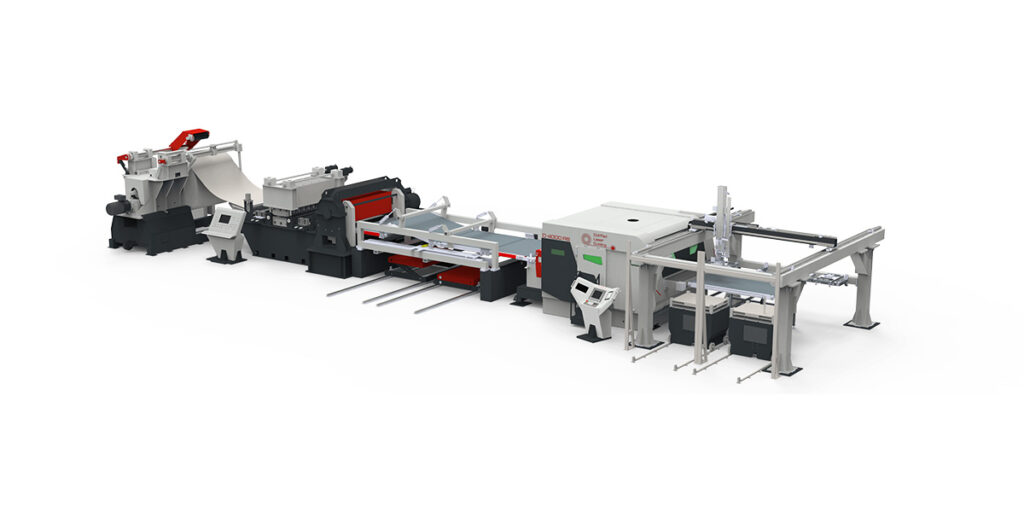

The high accuracy laser cutting system is an advanced technology designed to precisely cut intricate shapes from a variety of materials such as metal, plastic, ceramics and composites.

Laser cutting in the automotive industry is an advanced technology that plays a key role in the production of modern vehicles. Using a high-energy laser beam, the process makes it possible to precisely, quickly and efficiently cut complex shapes out of various materials such as steel, aluminum and composites.

The main advantages of laser cutting in the automotive industry are:

- High precision: It enables the cutting of exact shapes with minimal tolerances, which is crucial for automotive components that must fit perfectly with other parts.

- Speed: Laser cutting is much faster than traditional cutting methods, speeding up the production process and increasing productivity.

- Cleanliness and edge quality: Provides smooth and clean edges without the need for further processing, reducing production time and costs.

- Flexibility: Allows easy adaptation to different designs and materials, which is essential in the rapidly growing automotive industry.

- Waste minimization: Thanks to precision cutting, the amount of material waste is significantly reduced, which has a positive impact on production costs and environmental protection.

Laser cutting is used in many stages of automobile production, from body fabrication to interior components to mechanical details. Thanks to this technology, the automotive industry can produce lighter, stronger and more technically advanced vehicles while meeting high quality and safety standards.