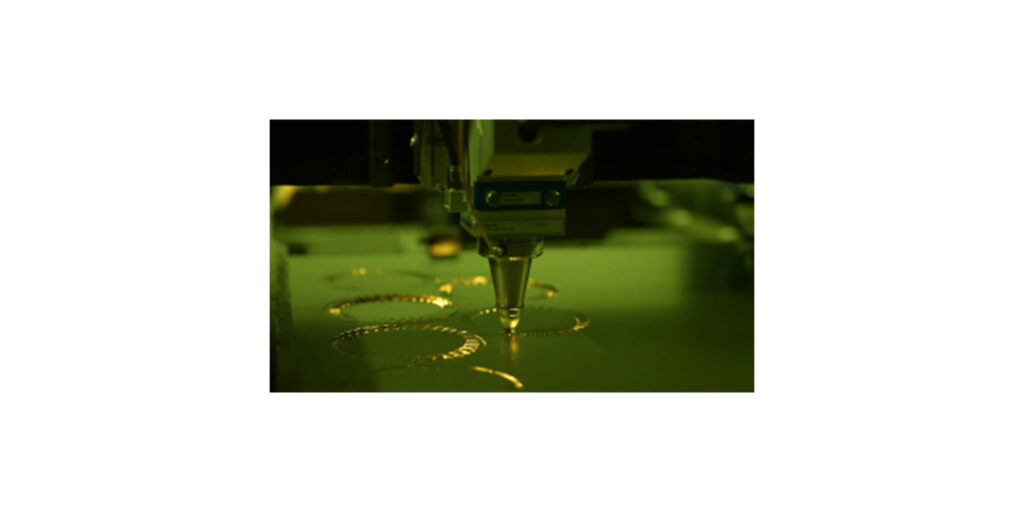

- Faster piercing function

- Real-time simulations

- Sheet clamping mechanism to secure sheets during the cutting process

- Multilingual HMI option

- Nesting software from Metalix and Sigmanest (Lantek)

- Automatic calibration

- Drop hole error

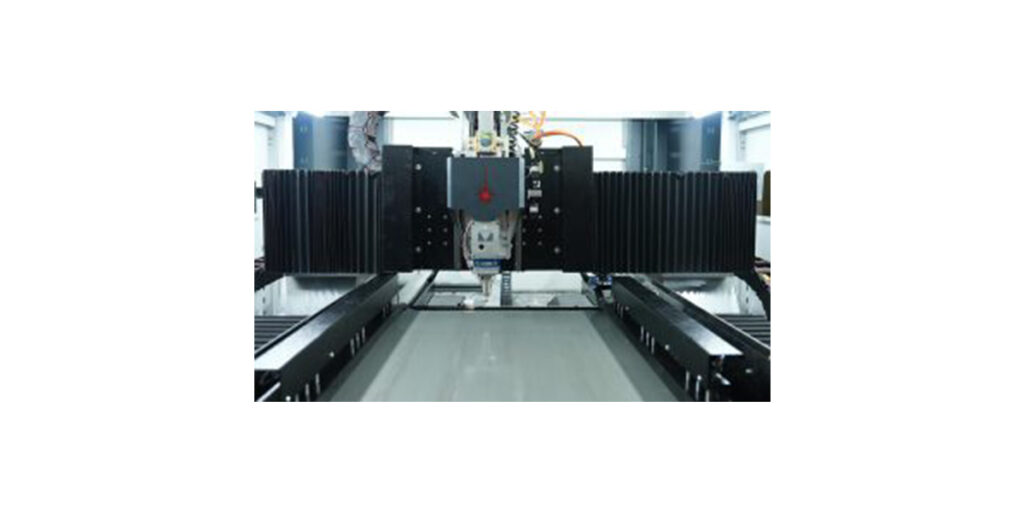

- The working area of the machine is moved manually