Various technological solutions for automating grinding, deburring and satin finishing processes

Grinding

Various technological solutions for automating grinding, deburring and satin finishing processes are based on the use of a rotary table and its high capacity in combination with our work unit models or integrated with a robotic unit. The use of this type of processing system, either alone or in combination, can be the right solution for creating an efficient, flexible and user-friendly machine.

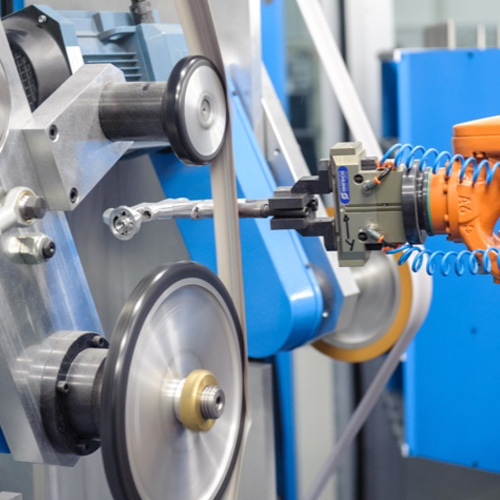

IR

Robotic Cell (IR)

The most flexible solution for confronting delicate and complex grinding operations; the goal is to make them increasingly efficient and productive. Robotic cells stand out for their versatility in facing the grinding process.

Thanks to special grinding units, it is possible to shift the tool needed in the process from, for example, simple grinding discs to flap wheels, scotch-brite fleeces, etc.

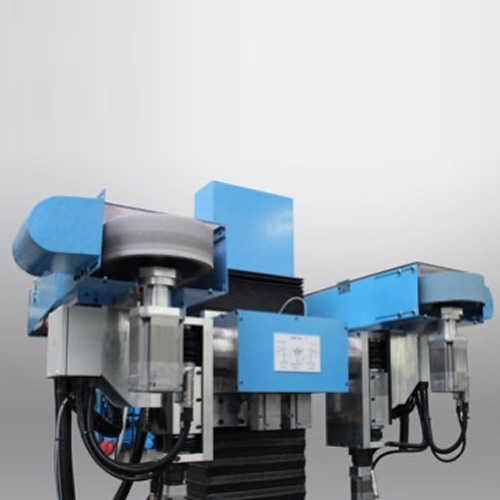

TR+CNCS

Indexable rotary table with C.N.C.S. type grinding unit.

The ideal solution for automating a multi-phase polishing process with a single unit.

A technological evolution that combines the advantages of an indexed rotary table with the innovative features and flexibility of CNCS multi-axis grinding units.

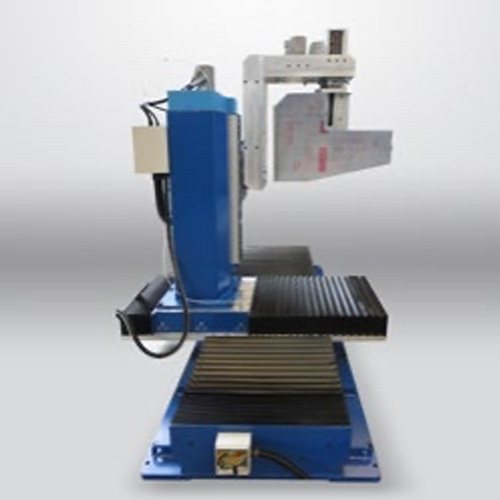

TR+CSL

Indexed rotary table with C.S.L. type grinding unit.

This type of machine should be considered the first level of automation of the grinding process thanks to the rotary table.

The operating units arranged around the rotary table are necessary to complete each stage of the grinding process and, depending on the nature of the product and the cycle time, have different features.

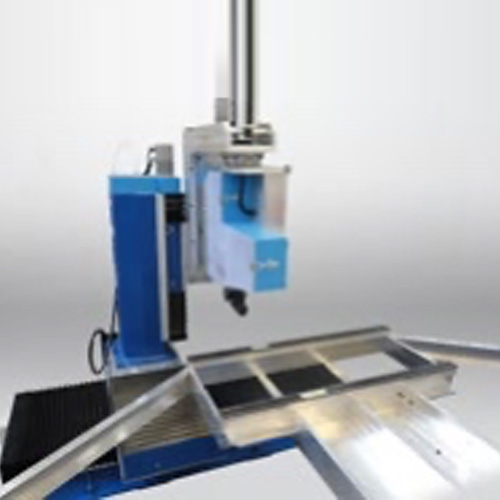

TR+CNC-RAD

Indexed rotary table with C.N.C.-type RAD/REC grinding unit for sinks and bowls/tubs.

Ideal for grinding and satin finishing of sinks and similar products.

TR+CNC-REC

Indexed rotary table with C.N.C.-type RAD/REC grinding unit for sinks and bowls/tubs.

These special units can operate alone or in combination with a work table or to a rotary table. The arbor mounting can be fixed or moved by one or two controllable axes, which can be integrated with the axes of the grinding unit.